- Home

- About Us

- Machinery

- Paper Cone Production Line

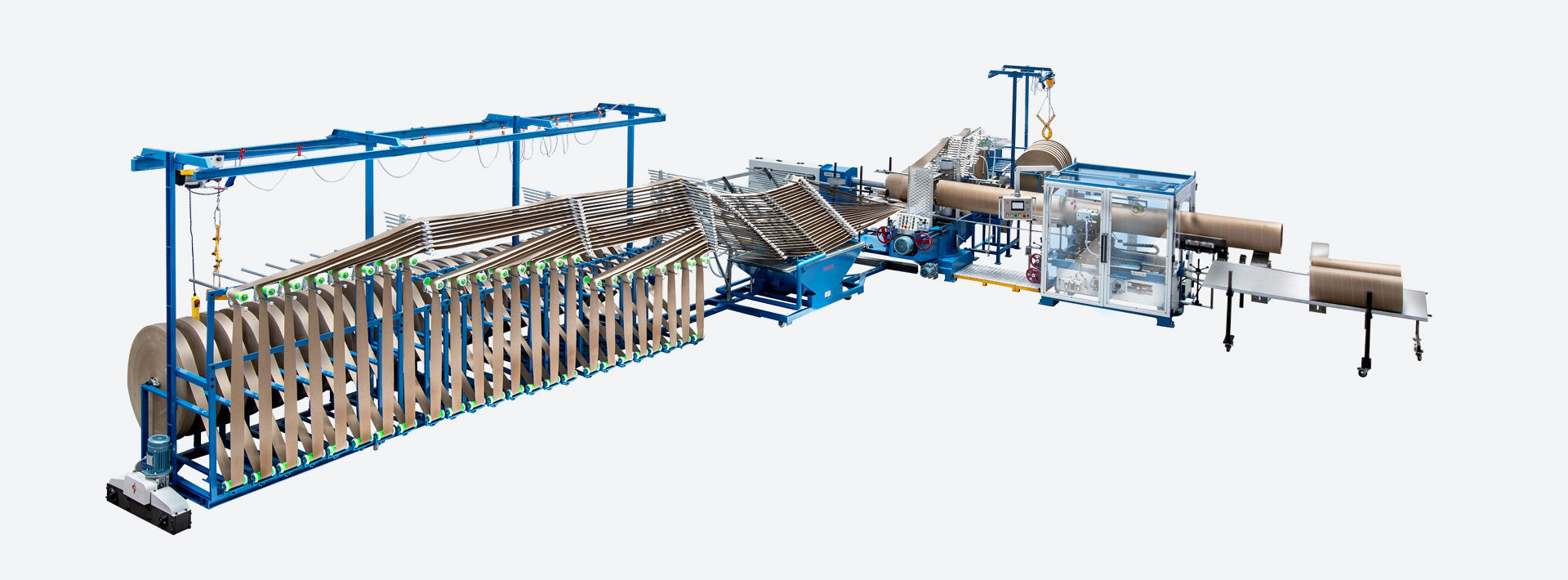

Automatic Paper Cone Plant

-

Automatic Paper Cone Making Machine with Online Drier

-

Automatic Paper Cone Finishing Machine (Twin Index)

Semi Automatic Paper Cone Plant

-

- Paper Tube & Core Production Line

- Composite Can Production Line

- Pulp Moulding Production Line

- Tableware Production Line

- Edge Protector Production Line

- Fibre Drum Production Line

- Square Drum Production Line

- Paper Cone Production Line

- Products

- Projects

- CSR

- Contact Us

Expert Tips for Choosing the Right Egg Tray Machine for Your Business

If you’re planning to start an egg tray production business, selecting the right egg tray machine is one of the most important decisions you will make. With a wide range of options available in the market, understanding the key factors to consider will ensure you invest in the best equipment suited to your production needs.

In this blog, we will share expert insights on what to look for when selecting an egg tray machine that matches your business goals and requirements.

1. Assess Your Production Capacity

One of the first factors to evaluate is the production capacity of the egg tray machine. Consider the number of trays your business needs to produce daily, weekly, or monthly.

Egg tray machines come with varying capacities, ranging from semi-automatic to fully automatic machines. If you’re starting small, a semi-automatic machine with a production capacity on the lower end (around 1,300 trays/hour) may be sufficient. For larger operations, a fully automatic machine with a higher capacity (up to 8000 trays/hour) is ideal to meet increasing market demand.

Expert Tip:

It’s smart to invest in a machine with a slightly higher capacity than your current needs to accommodate future growth. This allows you to scale up production without needing an immediate upgrade.

2. Raw Material Compatibility

The type and quality of raw materials used in egg tray production can significantly affect the quality of the final product. The most common raw material is waste paper, which can come from newspapers, books, and cardboard boxes. These materials are broken down into pulp, which is then moulded into egg trays.

Make sure to choose a machine that can handle a wide range of raw materials, including different types of waste paper and cardboard. This will give your business flexibility in sourcing affordable and readily available materials.

Expert Tip:

For higher durability, look for machines that allow adding additives to improve moisture resistance and overall tray strength, especially if you’re working with wet or greasy conditions.

3. Machine Design and Automation

Semi-Automatic Machines:

Semi-automatic egg tray machines offer a balance between automation and labour, making them a cost-effective choice for medium-scale businesses. These machines can produce up to 1300 trays per hour with some manual intervention.

Fully Automatic Machines:

Fully automatic egg tray machines are ideal for high-volume production and offer the highest efficiency. With capacities of up to 8,000 trays per hour, these machines require minimal human intervention, enhance production efficiency, ensure consistent quality and reduce labour costs.

Expert Tip:

If your goal is to minimize labour and boost production, investing in a fully automatic model is the way to go. This will ensure uniform production and help scale your operations with ease.

4. Look for Energy Efficiency

Energy consumption is another critical factor to consider, as it directly affects your production costs. Machines that consume less power while maintaining high output are essential for optimizing profitability.

Certain machines come equipped with automatic shutdown and standby modes to conserve energy during idle periods. Choosing an energy-efficient machine will lower your operational costs in the long run.

Expert Tip:

Machines with efficient drying systems not only reduce energy consumption but also speed up the drying process, further enhancing productivity.

5 . Consider the Machine’s Moulding System

The moulding system is the heart of the egg tray production process. Ensure that the machine you select offers high precision and accuracy in moulding to achieve uniform and consistent tray quality. Machines with advanced moulding technology will provide a superior finish, reducing the chances of defects and wastage.

Expert Tip:

Look for machines equipped with interchangeable moulds that allow you to produce trays in different sizes and shapes. This flexibility can help you cater to varying customer needs and diversify your product range.

6. Maintenance and Support

Regular maintenance is crucial for ensuring the long-term functionality of your egg tray machine. Downtime caused by machine malfunctions can severely impact your production schedule, so it’s essential to have reliable customer support and access to spare parts.

Choose a machine from a reputable manufacturer like Sodaltech, which offers after-sales service, technical support, and easy access to spare parts. This ensures that any issues can be promptly resolved, minimizing production delays.

Expert Tip:

Check whether the manufacturer provides timely support and training for machine operators. This will help your team stay up-to-date on best practices for operating and maintaining the machine, improving overall efficiency.

7. Verify Compliance with Industry Standards

It’s essential to ensure that the egg tray machine you choose complies with local and international manufacturing standards. Machines that ensure precise engineering and meet environmental standards are essential, especially when producing packaging for industries where safety and durability are critical.

Expert Tip:

Choose machines with ISO certifications or CE markings, which demonstrate that the equipment meets high industry standards for quality, safety, and sustainability.

8. Read Customer Reviews

Before making your final decision, take the time to research customer feedback on the machine model you’re considering. Reviews and testimonials provide valuable insights into real-world performance, potential issues, and overall customer satisfaction.

Expert Tip:

Look for machines with positive feedback regarding durability, performance, and manufacturer support. This will give you confidence in your investment and ensure peace of mind as you integrate the machine into your operations.

Conclusion

Choosing the right egg tray machine is essential for the success of your business. By evaluating factors such as production capacity, raw material compatibility, machine design, energy efficiency, and maintenance requirements, you can make an informed decision that aligns with your operational goals.

At Sodaltech, we are committed to providing high-performance egg tray machines that help businesses thrive. Whether you’re starting small or planning large-scale production, our range of machines offers solutions tailored to your specific needs.

Contact us today to learn more about how our egg tray machines can help drive your business forward.

ENQUIRY FORM SODALTECH

Don't hesitate to contact us if you would like to know more about what we can do for you.