- Home

- About Us

- Machinery

- Paper Cone Production Line

Automatic Paper Cone Plant

-

Automatic Paper Cone Making Machine with Online Drier

-

Automatic Paper Cone Finishing Machine (Twin Index)

Semi Automatic Paper Cone Plant

-

- Paper Tube & Core Production Line

- Composite Can Production Line

- Pulp Moulding Production Line

- Tableware Production Line

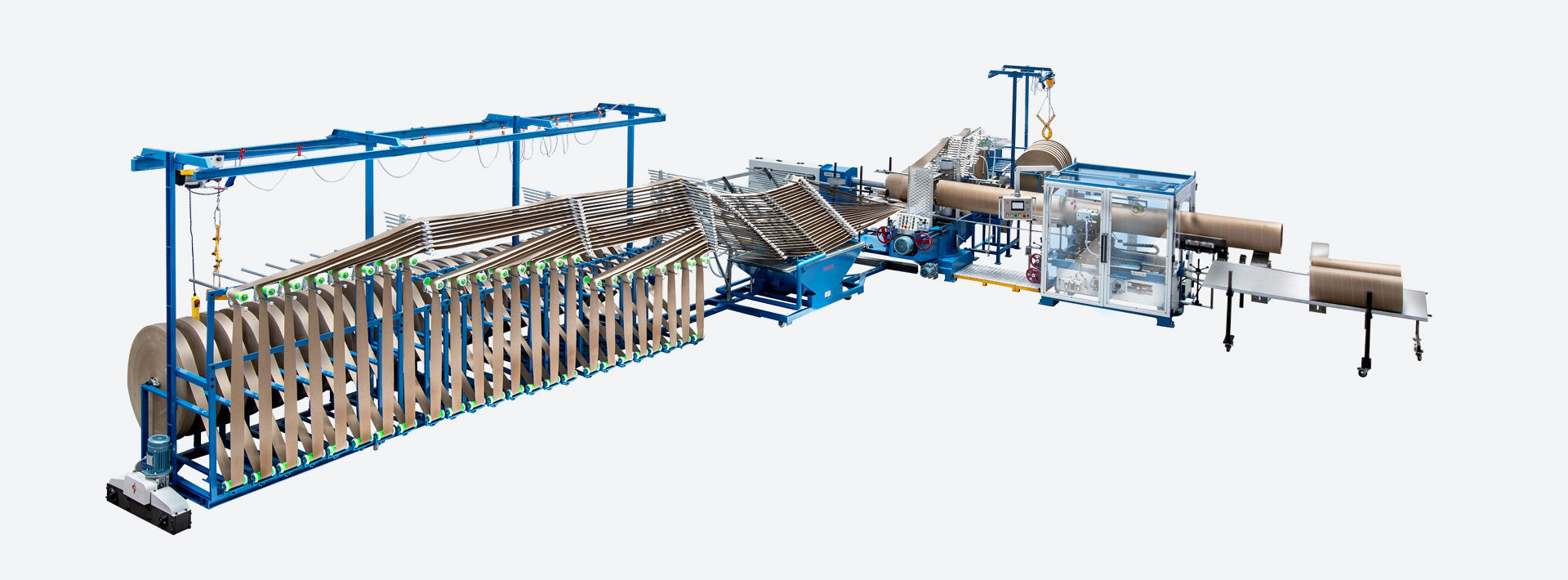

- Edge Protector Production Line

- Fibre Drum Production Line

- Square Drum Production Line

- Paper Cone Production Line

- Products

- Projects

- CSR

- Contact Us

Step-by-Step Process of How Our Paper Edge Protector-Making Machine Works

In today’s logistics and packaging industries, edge protectors play an essential role in safeguarding products during storage and transport. Sodaltech’s Paper Edge Protector Making Machine offers an efficient, eco-friendly solution for producing these protective materials. But how exactly does this machinery work? Let’s dive into the step-by-step process of how our innovative system transforms raw paper materials into durable edge protectors, perfect for a wide range of packaging needs..

Know about our Edge Protector production line

Sodaltech’s edge protector protection line is a convenient option for manufacturing cost-effective edge protectors for product protection, warehousing and transit needs. It is highly versatile to manufacture a wide range of edge protectors like V, U, and C profiles flat boards, and wrap-around edge boards including waterproof laminated edge boards.

The production line consists of:

- Reel unwinding stand

- Electric hoist for reel holding

- Outer layer unwinding stand

- Cascade type gluing system suitable for hot and cold glue

- On line printer

- Forming section

- Online cut off unit

Step 1: Raw Material Unwinding

The process begins with the Reel Unwinding Stand, where large rolls of paper are fed into the machine. The stand is equipped with an electric hoist to simplify the loading of the paper reels, ensuring smooth and consistent feeding. The machine allows for multi-layer unwinding, with an outer layer unwinding stand for different layers of paper material that combine to form the edge protectors…

Step 2: Glue Application

The raw material then enters the Gluing System, which uses a cascade-type mechanism suitable for both hot and cold glue. The layers of paper are carefully bonded together to achieve the necessary strength and durability.

The gluing process ensures that the paper maintains a rigid form that can withstand the pressures of transportation and handling.

Step 3: Forming Section

Once glued, the paper moves to the Edge Protector Forming Machine, which shapes the glued material into various profiles like V, U, and C shapes. This machine is:

- Equipped with Variable Speed A.C. Drive: It controls the forming rollers for precision shaping.

- Provision for Interchangeability: Easily switch between different profile designs based on the type of edge protector required.

- Pneumatic Control: This feature allows for easy engagement and disengagement of the forming rollers, ensuring the correct shape and pressure are applied to the edge protectors.

- Equipped with Variable Speed A.C. Drive: It controls the forming rollers for precision shaping.

- Provision for Interchangeability: Easily switch between different profile designs based on the type of edge protector required.

- Pneumatic Control: This feature allows for easy engagement and disengagement of the forming rollers, ensuring the correct shape and pressure are applied to the edge protectors.

Step 4: Edge Protector Rotary Notching (Optional)

For applications requiring circular edge protection, such as wrap-around edge protectors, the machine includes an Edge Protector Rotary Notching Machine. This high-speed machine precisely notches the edge protectors, ensuring they fit around circular goods like drums or pipes.

Key features:

- Durable Rotary Cutting System: Provides smooth and precise cuts.

- Quick Profile Adjustment: Easily adjust thickness based on the material.

- Collection Stand: Once notched, products are delivered and stacked neatly, ready for packaging

Step 5: On-line Printing (Optional)

Once the edge protectors are formed, they can pass through the On-line Printer to apply branding, instructions, or other essential markings. This customizable feature allows companies to enhance their brand presence directly on their packaging materials.

Step 6: Cutting Section

After the edge protectors are formed, they proceed to the On-line Edge Protector Cut-off Unit. This section uses a servo-controlled knife for precision cutting, ensuring that the protectors are cut into the desired length. The cut-off unit is synchronized with the forming machine, allowing continuous production without stopping the process.

Key features of the cutting unit:

- Quick Interchange of Cutting Tools: This makes switching between different product sizes seamless.

- Integrated Delivery Conveyor: After cutting, edge protectors are transferred onto the conveyor for easy collection and stacking.

Step 7: Finished Product

Once the edge protectors are cut to size and shaped, they are ready for packaging and distribution. The finished products, whether flat boards, V or U profiles, or wrap-around edge boards, are durable and waterproof, making them ideal for protecting products during storage and transit.

Why Choose Sodaltech’s Edge Protector Machine?

- High Production Efficiency: Capable of bulk production with consistent quality.

- Customizable Profiles: Multiple shapes (V, U, C) and sizes to meet varied packaging needs.

- Easy Installation and Training: User-friendly machine with easy installation and training processes.

- Environmentally Friendly: Uses sustainable raw materials and starch-based adhesives.

- Performance: Designed for long-term reliability and consistent performance.

Conclusion

Understanding how the Paper Edge Protector Making Machine works showcases the engineering behind this powerful packaging solution. From reel unwinding to precision forming and cutting, every step in the process is designed to ensure high-quality, durable edge protectors that meet the demands of modern packaging needs.

If you’re looking to improve your packaging efficiency and reduce product damage during transit, contact Sodaltech today and discover how our innovative machinery can revolutionize your operations!

ENQUIRY FORM SODALTECH

Don't hesitate to contact us if you would like to know more about what we can do for you.