- Home

- About Us

- Machinery

- Paper Cone Production Line

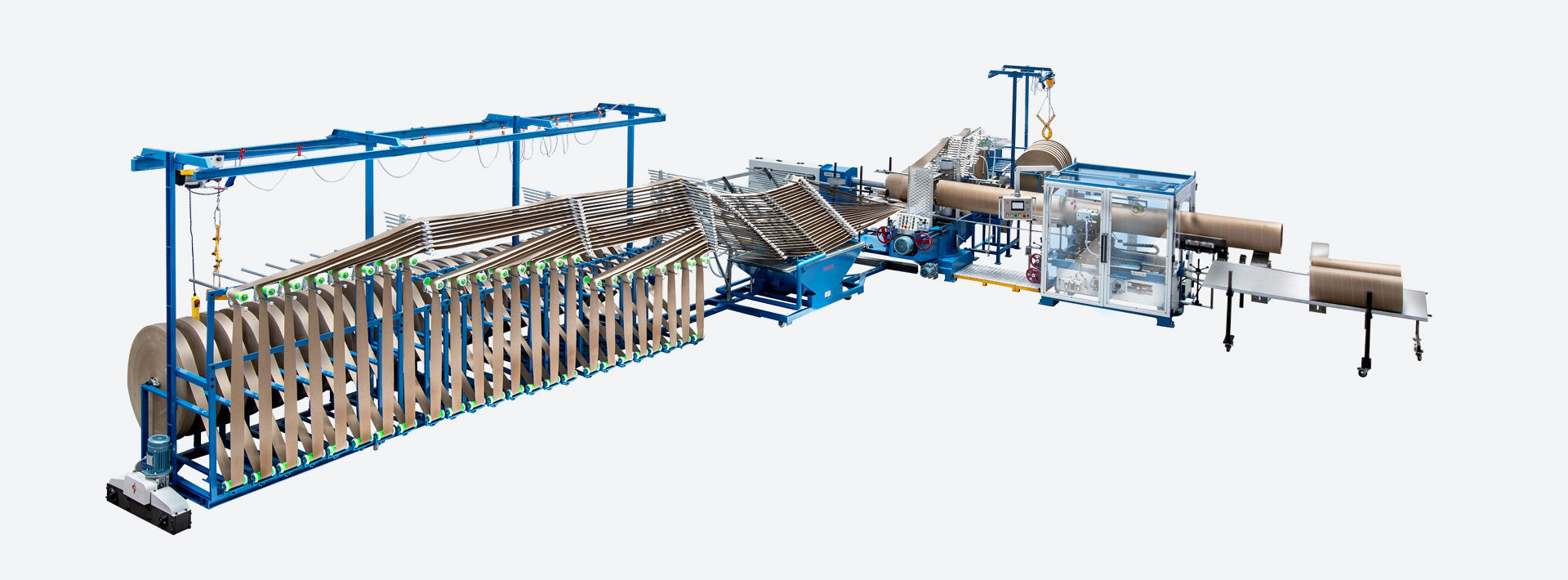

Automatic Paper Cone Plant

-

Automatic Paper Cone Making Machine with Online Drier

-

Automatic Paper Cone Finishing Machine (Twin Index)

Semi Automatic Paper Cone Plant

-

- Paper Tube & Core Production Line

- Composite Can Production Line

- Pulp Moulding Production Line

- Tableware Production Line

- Edge Protector Production Line

- Fibre Drum Production Line

- Square Drum Production Line

- Paper Cone Production Line

- Products

- Projects

- CSR

- Contact Us

10 Reasons Why Molded Pulp Packaging Is the Future

Molded pulp packaging is an innovative, eco-friendly solution made from recycled paper, gaining popularity across various industries. Its key advantages include customization, versatility, and cost-effectiveness, making it ideal for protecting and transporting goods.

The material’s moldable nature allows for intricate designs and shapes, providing customized solutions that enhance product protection during transit and add uniqueness to the packaging.

In this article let us look into 10 reasons why molded pulp packaging is the future.

What is Molded Pulp Packaging?

Molded pulp packaging, also known as molded fiber packaging, is a process where recycled paper fibers are mixed with water and molded into specific shapes and forms. It is an excellent alternative to plastic and styrofoam packaging as it offers several advantages. The packaging is lightweight, biodegradable, and recyclable, ensuring minimal environmental impact.

The manufacturing process of molded pulp packaging involves several steps. Recycled paper is first converted into pulp, mixed with water, and then molded into the desired shape using molds. The molded products are then dried and finished to achieve the desired strength and thickness. This process can produce a wide range of packaging solutions, including egg trays, fruit trays, tableware, industrial packaging and medical disposables.

Furthermore, molded pulp packaging is not only environmentally friendly but also cost-effective. The use of recycled materials reduces the overall production costs, making it a budget-friendly option for businesses looking to minimize their packaging expenses. Additionally, the lightweight nature of molded pulp packaging can help reduce shipping costs, as it adds minimal weight to the overall package, resulting in potential savings for companies involved in transportation and logistics.

1. Customization and Design Flexibility

Molded pulp packaging can be tailored to meet the specific needs of different industries and products. It can be easily molded into various shapes and sizes, allowing for custom packaging solutions. Companies can incorporate branding elements and product-specific design features to enhance the overall presentation and protection of their products.

Furthermore, molded pulp packaging offers excellent cushioning and protection for fragile items during shipping and handling. The shock-absorbing properties of molded pulp help prevent damage and breakage, reducing product returns and enhancing customer satisfaction. This level of protection is crucial for companies shipping delicate or high-value products.

2. The Environmental Impact of Molded Pulp Packaging

Molded pulp packaging stands out as an environmentally-friendly option compared to traditional packaging materials. Its sustainability and waste reduction potential make it a preferred choice for companies looking to minimize their carbon footprint.

When considering the environmental impact of molded pulp packaging, it’s important to delve into the intricate details of its production process. The creation of molded pulp involves a unique method where recycled paper is mixed with water to form a slurry. This slurry is then molded into various shapes and dried to create the final packaging product. This process not only utilizes recycled materials but also minimizes water and energy consumption, making it a truly eco-friendly packaging solution.

3. Sustainability of Molded Pulp Packaging

One of the key advantages of molded pulp packaging is its sustainability. The packaging is made from recycled materials, reducing the demand for fresh paper and reducing deforestation. Additionally, the packaging is fully biodegradable and compostable, ensuring it does not contribute to landfill waste.

Molded pulp packaging is also energy-efficient to produce. The manufacturing process requires less energy compared to other packaging materials, further reducing its environmental impact.

Furthermore, the biodegradability of molded pulp packaging plays a significant role in reducing pollution. When disposed of, the packaging breaks down naturally without releasing harmful toxins into the environment, unlike traditional plastic packaging that can take hundreds of years to decompose.

4. Waste Reduction and Recycling Potential

Molded pulp packaging not only reduces waste but also has the potential to be recycled multiple times. After its useful life as packaging, the molded pulp can be recycled along with other paper products, allowing for a circular economy. Through recycling, the packaging can be transformed into new molded pulp products, extending its lifespan and reducing the need for additional raw materials.

By choosing molded pulp packaging, companies can make a tangible impact on reducing their environmental footprint and promoting a more sustainable future. The versatility, recyclability, and eco-friendly nature of molded pulp make it a frontrunner in the quest for greener packaging solutions.

5. Cost-Effectiveness of Molded Pulp Packaging

In addition to its environmental benefits, molded pulp packaging is also cost-effective for businesses. The production costs and long-term financial benefits of using this packaging solution make it a viable choice for companies of all sizes.

Businesses that switch to molded pulp packaging not only contribute to sustainability efforts but also stand to benefit financially in various ways. Beyond the initial investment, the cost-effectiveness of this packaging solution becomes evident through its production efficiency and long-term savings.

6. Production Costs Compared to Traditional Packaging

The production costs of molded pulp packaging are often lower compared to traditional packaging materials. The use of recycled paper as the primary raw material significantly reduces the overall cost of production. Additionally, the simplicity of the manufacturing process helps to keep costs down.

Furthermore, the versatility of molded pulp allows for customization at a reasonable cost, catering to the specific needs of different products and industries. This adaptability not only enhances the packaging’s functionality but also adds value to the overall cost-effectiveness of the solution.

7. Long-Term Financial Benefits

Opting for molded pulp packaging can provide long-term financial benefits for businesses. The lightweight nature of the packaging reduces transportation costs, as it is lighter to carry and takes up less space. Moreover, the packaging’s protective properties reduce the risk of product damage during transit, reducing potential losses for businesses.

Additionally, the biodegradable nature of molded pulp packaging aligns with consumer preferences for eco-friendly products, potentially boosting brand reputation and customer loyalty. This positive association with sustainability can translate into increased sales and market competitiveness, further enhancing the long-term financial advantages of choosing molded pulp packaging.

8. Advancements in Molded Pulp Packaging Technology

The technology surrounding molded pulp packaging continues to evolve, enabling innovative solutions. Research and development in this field have led to advancements in materials, processes, and machinery. These advancements have enhanced the overall quality, durability, and performance of molded pulp packaging, making it a reliable and efficient choice for various applications.

Moreover, the lightweight nature of molded pulp packaging contributes to cost savings in shipping and logistics. By reducing the weight of packaging materials, companies can lower transportation costs and minimize their carbon emissions. This weight efficiency is particularly beneficial for e-commerce businesses that ship products in large volumes.

9. Versatility and Innovation in Molded Pulp Packaging

Molded pulp packaging offers versatility and innovation unparalleled by other packaging materials. The customization and design flexibility, coupled with advancements in technology, make it an exciting option for businesses.

One of the key advantages of molded pulp packaging is its sustainability. Made from recycled paper and cardboard materials, molded pulp is biodegradable and compostable, making it an environmentally friendly choice for companies looking to reduce their carbon footprint. This eco-friendly aspect not only appeals to environmentally conscious consumers but also aligns with corporate sustainability goals.

10. Consumer Demand for Eco-Friendly Packaging

Consumers are increasingly conscious of the environmental impact of packaging materials. They are actively seeking products packaged in eco-friendly materials, including molded pulp packaging. The perception that a company is committed to sustainability can positively influence consumer purchasing decisions.When consumers see products packaged in molded pulp, they feel a sense of relief knowing that they are making a more environmentally responsible choice. The natural and renewable fibers used in molded pulp packaging not only reduce the carbon footprint but also minimize waste. This aligns with the values of eco-conscious consumers who strive to make sustainable choices in their everyday lives.

Conclusion

As the demand for sustainable packaging solutions continues to rise, molded pulp packaging will play a crucial role in shaping the future of the packaging industry. Its ability to meet consumer expectations for eco-friendly materials, combined with its adaptability and cost-effectiveness, positions it as a frontrunner in the market.

ENQUIRY FORM SODALTECH

Don't hesitate to contact us if you would like to know more about what we can do for you.