How Pulp Moulding Supports a Circular Economy?

Introduction

In today’s rapidly evolving world, the focus is shifting toward sustainable manufacturing practices and circular economy models. Pulp moulding, a method that uses waste paper to create biodegradable products, is a prime example of how industries can adopt eco-friendly practices.

As a leading machinery manufacturer, Sodaltech is at the forefront of this transformation, helping companies attain their sustainable goals and contribute significantly to the circular economy…

In this article, we will explore how pulp moulding supports a circular economy and why it is a game-changer for the packaging industry, manufacturers, and the environment.

What is Pulp Moulding?

Pulp moulding is a process where waste paper and other fibrous materials are converted into products such as trays, cartons, and packaging materials. This process involves breaking down the raw materials into a slurry, which is then moulded into various shapes using customized moulds. The result is a biodegradable product that can be reused or easily decomposed, reducing the reliance on single-use plastics.

The Circular Economy: A Sustainable Model

A circular economy emphasizes reducing waste, reusing materials, and recycling to extend the lifecycle of products. Unlike a linear economy, which follows a “take, make, dispose” model, a circular economy aims to keep materials in circulation for as long as possible, thus minimizing waste and resource consumption. Pulp moulding fits perfectly into this model by turning paper waste into useful products that can be recycled again.

How Pulp Moulding Supports a Circular Economy

- 1. Reduces Waste through Recycling

Pulp moulding primarily uses waste paper as a raw material. Recycling paper waste into new packaging solutions significantly reduces the amount of paper that ends up in landfills. For machinery manufacturers like Sodaltech, this creates an opportunity to support industries in diverting waste from landfills, fostering a more sustainable environment.

- Example: Egg trays, fruit trays, and packaging inserts made from pulp moulding can be recycled multiple times, reducing the need for virgin materials.

- 2. Promotes Resource Efficiency

The pulp moulding machinery is designed to maximize material efficiency, ensuring that every ounce of raw material is utilized effectively. The machinery allows precise control over the slurry mix, enabling customization for different product specifications, which minimizes material waste and optimizes resource use for each production cycle..

- Example: By customizing moulds, manufacturers can optimize the use of pulp, producing different types of packaging with minimal material wastage.

- 3. Biodegradability: A Solution to Plastic Waste

One of the primary advantages of pulp moulding is the production of biodegradable products. Unlike plastic packaging, which can take hundreds of years to decompose, pulp-moulded products break down naturally. This reduces pollution and helps industries transition from plastic to eco-friendly alternatives.

- Example: Pulp-moulded products like protective packaging and horticultural pots decompose naturally, contributing to a zero-waste approach.

- 4. Cost-Effective Recycling for Manufacturers

For manufacturers, recycling can often be a costly process. However, pulp moulding provides a cost-effective recycling solution. With pulp moulding machines, industries can process paper waste in-house, reducing the costs associated with external recycling and waste disposal services. This makes it easier for manufacturers to adopt sustainable practices without significantly increasing production costs.

- Example: Pulp-moulded products like protective packaging and horticultural pots decompose naturally, contributing to a zero-waste approach.A company producing consumer goods can repurpose its own waste paper into pulp moulded packaging, reducing both material costs and waste disposal expenses.

- 5. Encourages Local Sourcing and Production

A key principle of the circular economy is localized production. Pulp moulding allows manufacturers to source waste paper locally, convert it into moulded products, and distribute these products within the region. This reduces the carbon footprint associated with long-distance transport and supports local economies.

Benefits of Pulp Moulding for the Environment and Businesses

- 1. Environmental Benefits

- Reduced Carbon Emissions: Pulp moulding uses less energy compared to plastic production, lowering carbon emissions.

- Lower Landfill Impact: With products that are biodegradable, pulp moulding helps decrease the burden on landfills.

- Regulatory Compliance: With increasing regulations on plastic waste, adopting pulp moulding can help businesses stay compliant with environmental standards.

- 2. Business Benefits

- Competitive Edge: By adopting sustainable packaging solutions, businesses can enhance their brand image and appeal to environmentally-conscious consumers.

- Cost Savings: Reusing waste paper reduces the need for new raw materials, leading to long-term cost savings.

- Regulatory Compliance: With increasing regulations on plastic waste, adopting pulp moulding can help businesses stay compliant with environmental standards.

Sodaltech’s Role in Advancing Pulp Moulding Technology

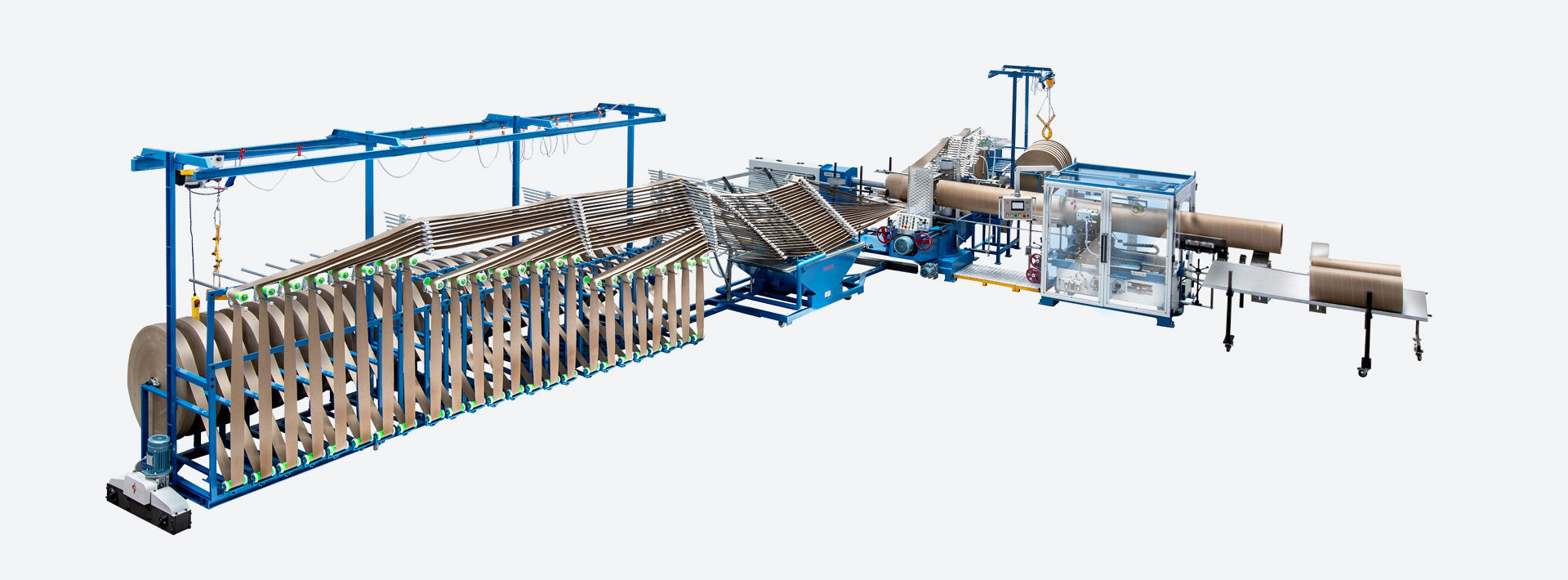

As a leading pulp moulding machinery manufacturer, Sodaltech is at the forefront of driving innovation in this field. Their quality machines are designed to process a wide range of fibrous materials into eco-friendly packaging solutions. By providing efficient and reliable equipment, Sodaltech empowers businesses to adopt sustainable practices that align with the principles of a circular economy.

Features of Sodaltech’s Pulp Moulding Machinery:

- Versatile Moulding Options: Suitable for creating diverse products like trays, containers, and packaging inserts.

- Energy Efficiency: Engineered to consume less energy, supporting eco-friendly production processes.

- Automated Systems: Streamlined production with minimal manual intervention ensures high productivity and consistency in quality.

Conclusion:

Pulp moulding is at the forefront of sustainable innovation, turning waste materials into valuable, eco-friendly packaging solutions. For manufacturers and businesses looking to align with the principles of a circular economy, pulp moulding technology offers an efficient and cost-effective way to reduce waste, conserve resources, and meet the growing demand for sustainability.

Take the next step towards sustainable production by partnering with Sodaltech. Contact us today to explore how our pulp moulding machinery can elevate your business while supporting a circular economy.