- Home

- About Us

- Machinery

- Paper Cone Production Line

Automatic Paper Cone Plant

-

Automatic Paper Cone Making Machine with Online Drier

-

Automatic Paper Cone Finishing Machine (Twin Index)

Semi Automatic Paper Cone Plant

-

- Paper Tube & Core Production Line

- Composite Can Production Line

- Pulp Moulding Production Line

- Tableware Production Line

- Edge Protector Production Line

- Fibre Drum Production Line

- Square Drum Production Line

- Paper Cone Production Line

- Products

- Projects

- CSR

- Contact Us

How to Choose the Right Machinery for Your Fibre Drum Manufacturing

Fibre drum manufacturing requires specialized machinery to ensure efficient and high-quality production. Choosing the right machinery for your manufacturing needs is crucial for your business’s success. In this article, we will guide you through the process of choosing the most suitable machinery for your fibre drum manufacturing operation.

Why Should You Choose The Right Machinery?

Selecting the appropriate machinery is vital for several reasons. Firstly, it determines the production capacity of your fibre drum manufacturing facility. The right machinery will allow you to meet your production volume requirements without compromising quality. With advanced automation and efficient production processes, modern machinery can significantly increase the output of your manufacturing facility, enabling you to fulfil large orders in a timely manner.

Secondly, choosing the right machinery ensures that your fibre drums are manufactured precisely and adhere to industry standards. High-quality machinery has advanced technologies that enable accurate cutting, glueing, and shaping of the drum components.

Lastly, investing in reliable machinery reduces downtime and maintenance costs in the long run, contributing to the overall efficiency of your operation. Modern machinery is designed to be robust and durable, minimizing the risk of breakdowns and the need for frequent repairs.

Understanding the Basics of Fibre Drum Manufacturing

Before considering the machinery selection process, it’s essential to have a solid understanding of the basics of fibre drum manufacturing. Fibre drums are containers made from renewable materials such as paperboard and steel. They are widely used in various industries to store and transport bulk goods. The manufacturing process involves several key components that contribute to the final product’s quality and durability.

One of the key components in fibre drum production is the drum body. The drum body is typically made from multiple layers of paperboard that are carefully glued together. Because of its strong and sturdy structure, the drum can support the weight and pressure of the products it will be holding. The paperboard that is specifically chosen for the construction of drums is strong and resistant to moisture, meaning that the drum will hold up even under harsh conditions.

In addition to the drum body, fibre drums also consist of bottom and top rings, covers, and locking mechanisms. These components are essential for securing the drum’s contents and protecting them during transportation. The bottom and top rings provide structural support to the drum, preventing it from collapsing under heavy loads. The covers, usually made from steel or plastic, seal the drum and protect its contents from dust, moisture, and other external factors. The locking mechanisms ensure the drum remains tightly sealed, preventing any leakage or spillage.

Evaluating Your Manufacturing Needs

Evaluating your specific manufacturing needs is crucial before starting the machinery selection process. This evaluation will help you determine the right specifications to meet your requirements.

Understanding the intricacies of your manufacturing process is essential for optimizing efficiency and productivity. By looking deep into the details of your production requirements, you can identify areas for improvement and innovation.

Assessing Your Production Volume

The first step in evaluating your manufacturing needs is to assess your production volume. Determine the number of fiber drums you need to produce daily, weekly, and monthly. This information will help you choose machinery to handle your desired output without causing bottlenecks or delays.

Furthermore, analyzing historical production data and forecasting future demand trends can provide valuable insights into potential fluctuations in production volume. This approach enables you to scale your manufacturing operations effectively.

Considering Your Product Specifications

Another vital consideration is your product specifications. The size, shape, and design of your fiber drums will impact the type of machinery required. Additionally, you need to consider factors such as printing capabilities, customization options, and any unique requirements specific to your industry or customers.

Collaborating with design and engineering teams to align product specifications with manufacturing capabilities is crucial for ensuring seamless production processes. Fostering cross-functional communication can streamline operations and enhance product quality.

Exploring Several Units in the Machinery

Now that you clearly understand your manufacturing needs, it’s time to explore the several units in the machinery. Let us look into each:

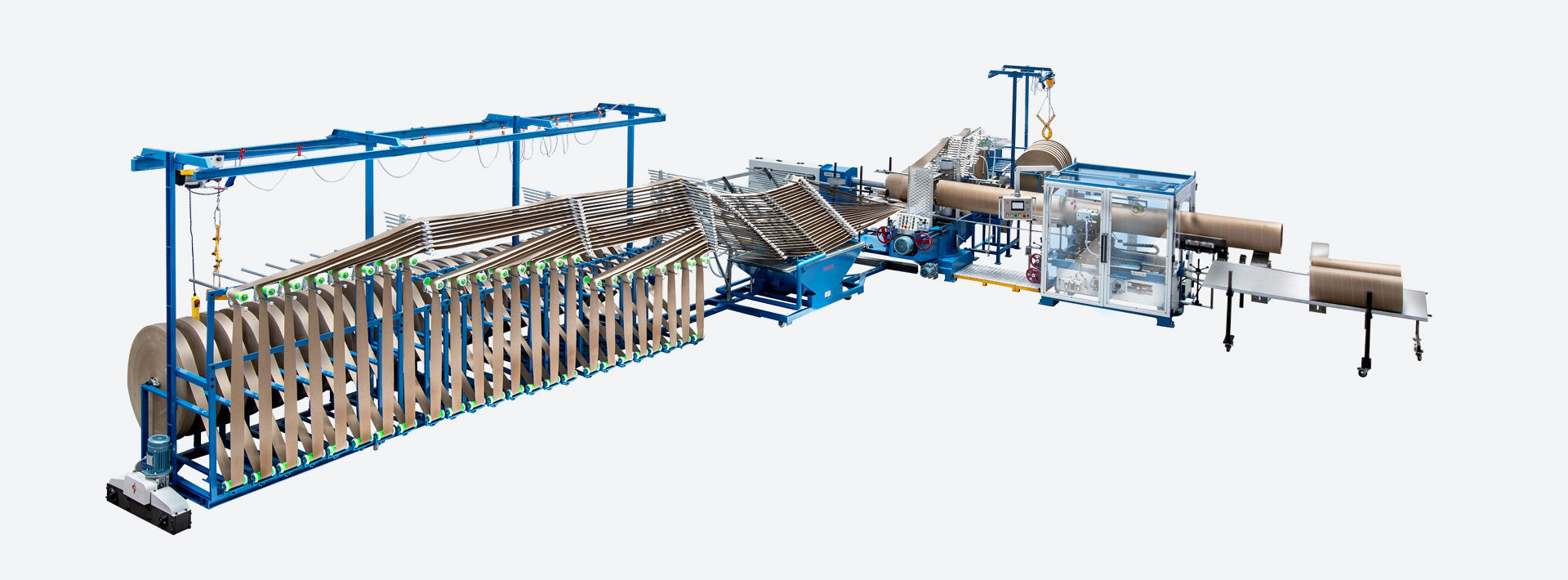

Fibre Drum Body Maker:

The Fibre Drum Body Maker is designed to ensure precise and efficient production of fibre drum bodies. This machine uses advanced technology to maintain consistent quality, producing durable and reliable drums that meet industry standards. Its high-speed operation and automated processes reduce manual labour, enhancing productivity while minimizing errors. The machine’s robust construction and user-friendly interface make it easy to operate and maintain. It can accommodate various drum sizes with adjustable settings, providing versatility for different production needs. This unit is essential for manufacturers seeking to deliver top-quality fibre drums efficiently and cost-effectively.

Bottom Lid Fixing Machine:

The Bottom Lid Fixing Machine, a symbol of durability, is designed to provide a secure and reliable attachment of the bottom lid to fibre drums. Its precision engineering ensures that each lid is firmly and accurately fixed, thereby enhancing the overall strength and stability of the drum. With its durable construction and straightforward operation, this machine is built to last, offering consistent performance. It’s an essential component for manufacturers aiming to produce high-quality fibre drums that meet rigorous industry standards.

Ring Fixing and Beading Machine:

The Ring Fixing and Beading Machine greatly enhance the integrity and durability of fibre drums. Rings are precisely fixed and beaded onto the drum using this machine, strengthening and lengthening its structure. The automated procedure guarantees consistent application, which lowers the possibility of errors and inconsistencies. The machine can easily handle high production quantities because of its high-efficiency design. It is dependable and indispensable equipment for producers who value quality and dependability in their fibre drum manufacturing operations because of its strong construction and user-friendly design.

Disc Cutting Machine:

A disc-cutting machine is essential for cutting the discs used in fibre drums. It guarantees that every disc is precisely sliced, ensuring a flawless fit and maximum performance from the drum. The machine’s strong structure guarantees lifespan and dependability, while its excellent accuracy and speed boost production efficiency. It can handle a range of disc sizes because of its configurable cutting settings, giving it flexibility for diverse industrial needs. This machinery is essential for producers who want to achieve high standards and efficient output in their fibre drum manufacturing operations since it is simple to run and maintain.

Factors to Consider When Choosing Machinery

Choosing the right machinery involves considering several factors that go beyond production volumes and product specifications. Here are key considerations to ensure that the machinery you choose aligns perfectly with your manufacturing needs:

Here are 5 factors one must consider when choosing machinery

- Technological advancements

One significant factor to take into account is the technological advancements in the machinery. With rapid innovations in the manufacturing industry, opting for machinery equipped with the latest technology can enhance efficiency, precision, and overall productivity. Upgrading to modern machinery can also future-proof your operations, ensuring you stay competitive in the market.

- Cost and Budget Considerations

One of the most critical factors to consider is the cost and your budget. Determine the amount you are willing to invest in machinery and consider the return on investment you expect. Always keep in mind that there are continuous conservation and repair costs in addition to the initial outlay. Carrying out a cost-benefit analysis is important to evaluate the long-term financial effects of your machinery investment.

- Space and Installation Requirements

Use the available space in your manufacturing facility and the machinery installation requirements. Some machines may require specific support structures, power supply, or additional space for material handling. Ensure your facility can accommodate the chosen machinery without compromising safety or affecting the overall workflow. Efficient space utilization is essential for optimizing production processes and ensuring a seamless operational flow.

- Maintenance and Durability Factors

Maintenance and durability are crucial aspects to evaluate when choosing machinery. Look for machines that are easy to maintain, have readily available spare parts, and are known for their reliability. Consider the machinery’s longevity and ability to withstand the demanding nature of fibre drum manufacturing. Investing in robust and durable machinery can help you minimize downtime, reduce maintenance costs, and prolong the lifespan of your equipment.

- Energy Efficiency

It is beneficial to assess the machinery’s energy efficiency. Opting for energy-efficient equipment reduces operational costs and aligns with sustainable manufacturing practices. By selecting machinery that consumes less energy and minimizes environmental impact, you can contribute to a greener manufacturing process and enhance your company’s reputation as an environmentally conscious organization.

Conclusion

Research states that “The fibre drums market is predicted to grow at a 5.7% compound annual growth rate (CAGR) from 2023 to 2033”

So if you are looking for the best fibre drum manufacturing machinery to make the best fibre drum then choosing Sodaltech Machinery is the best option.

Our goal atSodaltech is to satisfy your production demands by offering the best fibre drum machinery. Join us in our journey towards achieving greater efficiency, sustainability, and success in the industry.

We provide specialized solutions for all your machinery needs.

Contact us today!

ENQUIRY FORM SODALTECH

Don't hesitate to contact us if you would like to know more about what we can do for you.