- Home

- About Us

- Machinery

- Paper Cone Production Line

Automatic Paper Cone Plant

-

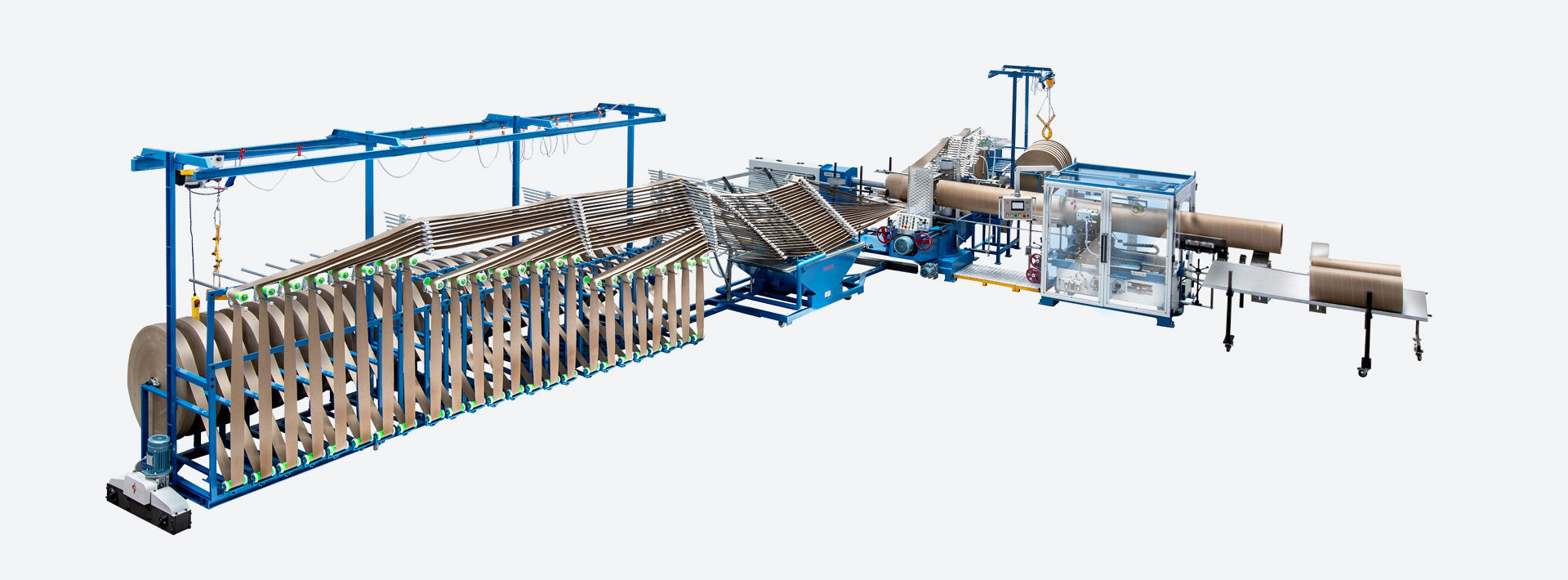

Automatic Paper Cone Making Machine with Online Drier

-

Automatic Paper Cone Finishing Machine (Twin Index)

Semi Automatic Paper Cone Plant

-

- Paper Tube & Core Production Line

- Composite Can Production Line

- Pulp Moulding Production Line

- Tableware Production Line

- Edge Protector Production Line

- Fibre Drum Production Line

- Square Drum Production Line

- Paper Cone Production Line

- Products

- Projects

- CSR

- Contact Us

How to Turn Waste into Profit: Transforming Paper Waste into Profitable Egg Trays

In today’s world, sustainability is a top priority for businesses and consumers alike. With increasing awareness about environmental conservation, companies are seeking innovative ways to reduce waste and minimize their carbon footprint. One such opportunity lies in transforming paper waste into profitable egg trays. This process not only helps in waste reduction but also offers a lucrative business model for entrepreneurs willing to invest in sustainable packaging solutions.

The Rising Demand for Sustainable Packaging

The global shift towards sustainability has spurred demand for eco-friendly packaging solutions. Governments and consumers alike are pushing for alternatives to plastic packaging, leading to a growing market for biodegradable and recyclable materials. Among these, moulded pulp packaging—made from recycled paper—has emerged as a popular choice.

Egg trays, in particular, are a vital component of the food packaging industry. Traditionally made from plastic or foam, these trays are now increasingly being produced using moulded pulp, which is both biodegradable and recyclable. This shift is driven by the global demand for sustainable packaging solutions, making the egg tray market a profitable venture for those looking to enter the industry.

The Environmental Benefits of Paper-Based Egg Trays

One of the primary advantages of transforming paper waste into egg trays is the significant environmental benefit it offers. Paper-based egg trays are:

- Biodegradable: Unlike plastic trays, which can take hundreds of years to decompose, paper-based trays break down naturally within a few months, reducing landfill waste.

- Recyclable: These trays can be recycled multiple times, contributing to a circular economy where materials are reused rather than discarded.

- Energy-Efficient: The production process for moulded pulp packaging typically requires less energy compared to plastic manufacturing, leading to lower carbon emissions.

By converting paper waste into egg trays, businesses can play a crucial role in reducing the environmental impact of packaging while tapping into a growing market.

Understanding the Process: From Paper Waste to Egg Trays

The transformation of paper waste into egg trays involves several key steps:

- Collection and Sorting of Paper Waste

Most manufacturers either purchase paper waste in bulk or use their own industrial waste, such as cardboard or packaging scraps. The collected waste is sorted to remove contaminants like plastic and metal ensuring that only clean and suitable paper fibers are used for production. This step is crucial for maintaining the quality of the final product.

- Pulping the Paper Waste

Once the paper waste is sorted, it is shredded and mixed with water to create a pulp. This pulping process breaks down the paper fibers into a slurry, which can then be moulded into various shapes. The pulp is the raw material used to create the egg trays.

- Moulding and Forming the Trays

The pulp is poured into specialized moulds using Egg Tray Moulding Machines that shape the slurry into egg trays. This is typically done using a vacuum or pressure moulding process, which ensures that the trays are formed with the necessary strength and durability to protect eggs during transport and storage.

- Drying and Finishing

After moulding, the trays are dried to remove excess moisture. This step is crucial for ensuring the trays’ structural integrity. Once dried, the trays may undergo additional treatments such as coating or printing for branding purposes. Finally, they are packaged and ready for distribution to egg producers and retailers.

Market Potential and Profitability

The egg tray market presents a lucrative opportunity for businesses, driven by the steady demand for eggs and the global shift towards sustainable packaging. According to industry reports, the global egg tray market is expected to grow at a compound annual growth rate (CAGR) of 4.5% over the next five years. This growth is fueled by increasing egg consumption and the push for eco-friendly packaging solutions.

Profit Margins and Revenue Potential

Businesses involved in the production of paper-based egg trays can expect profit margins of 20-30%, depending on production efficiency and market pricing. The initial investment in Paper Egg Tray Production Line and other equipment varies, but with careful planning and efficient operations, a return on investment can typically be achieved within 1-2 years.

Expanding Beyond Egg Trays

While egg trays are a primary product, the same production process can be adapted to create other types of moulded pulp packaging. This includes trays for fruits, electronic goods, and even industrial parts. By diversifying the product range, businesses can tap into multiple markets and further enhance profitability.

Setting Up Your Waste-to-Profit Business

To embark on this venture, entrepreneurs must carefully plan and consider various factors, including:

- Equipment and Space Requirements

Setting up a waste transformation business requires specialized equipment such as shredders, pulp moulding machines, and drying facilities. The amount of space needed will depend on the scale of operations but should accommodate material storage, equipment installation, and production processes.

- Legal and Environmental Compliance

Compliance with local regulations and environmental standards is crucial. Businesses must obtain the necessary permits and certifications to operate legally and sustainably. Implementing energy-efficient technologies and waste-reduction measures can also help minimize the company’s carbon footprint.

- Market Research and Customer Acquisition

Understanding the market dynamics is essential for success. Conducting thorough market research will help identify potential customers, pricing strategies, and competition. Building relationships with egg producers, retailers, and distributors is key to establishing a stable customer base.

Sustainability as a Selling Point

In today’s market, sustainability is not just a feature; it’s a selling point. Consumers are increasingly seeking out eco-friendly products, and businesses that can demonstrate a commitment to sustainability are likely to gain a competitive edge. By marketing paper-based egg trays as a sustainable alternative to plastic packaging, businesses can attract environmentally-conscious customers and build a strong brand reputation.

Technological Advancements

Advancements in technology are also driving the growth of the moulded pulp packaging industry. High-quality Egg Tray Making Machines and processes are being developed to increase production efficiency, reduce energy consumption, and enhance the quality of the final product. Businesses that invest in the latest technology will be well-positioned to capitalize on these advancements and maximize profitability.

Conclusion: Turning Waste into Wealth

Transforming paper waste into profitable egg trays is more than just a business opportunity; it’s a step towards a more sustainable future. By converting waste into valuable products, businesses can reduce their environmental impact while generating significant revenue. The egg tray market is growing, and those who seize this opportunity can establish themselves as leaders in the sustainable packaging industry.

For entrepreneurs looking to make a positive impact on the environment while building a profitable business, the waste-to-profit model offers a clear path forward. With the right strategy, resources, and commitment to sustainability, turning waste into wealth is not just possible—it’s the future of business.

Looking to start your own waste-to-profit venture? Sodaltech offers cutting-edge Egg Tray Making Machines and expert guidance to help you succeed. Contact us today to learn more!

ENQUIRY FORM SODALTECH

Don't hesitate to contact us if you would like to know more about what we can do for you.