Investing in Composite Can Making Machinery: What to Know

Introduction

The packaging industry is undergoing a significant shift towards sustainable solutions. Consumers are increasingly demanding eco-friendly options, and composite can making machinery offers a compelling way to meet this growing demand.

This blog post serves as your guide to investing in composite can making machinery. We’ll explore the fundamentals, delve into the financial considerations, discuss maintenance and lifespan factors, and guide you through the process. We’ll also emphasize the importance of operator training and safety.

Understanding Composite Can Making Machinery

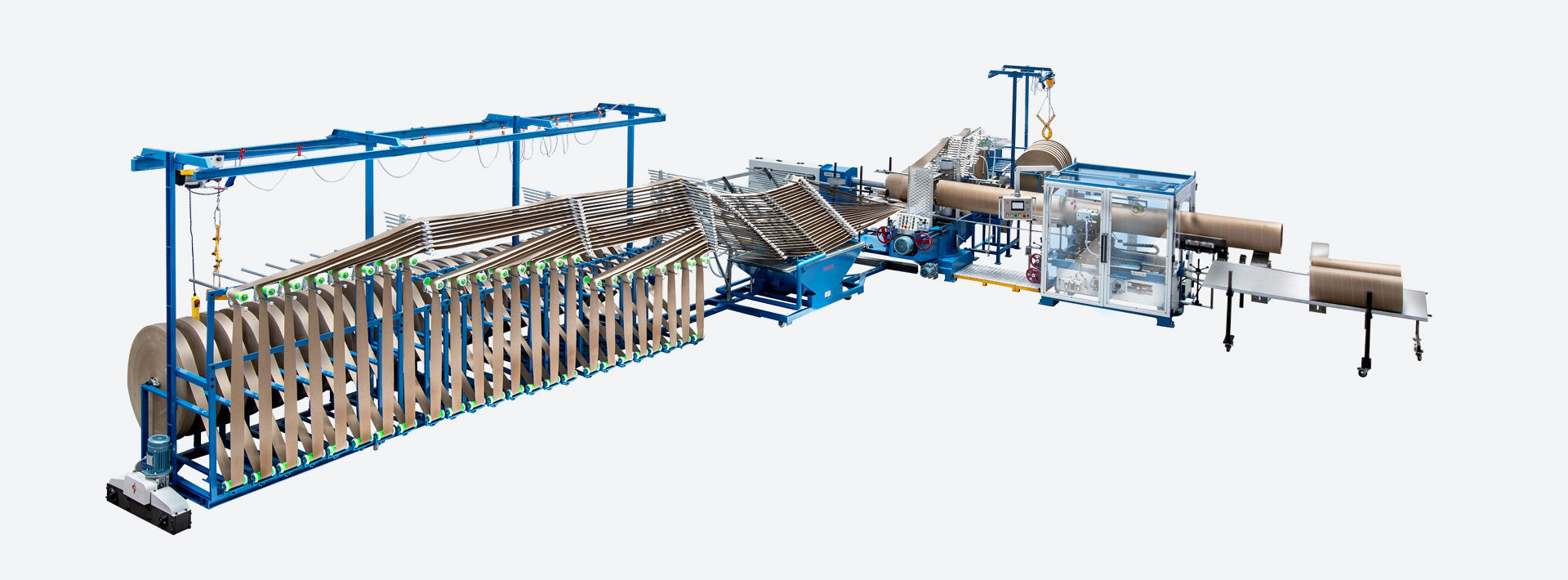

Composite can making machinery automates the production of composite cans, widely used for packaging food, beverages, and other consumer products. These machines typically consist of several key systems working in tandem:

-

- Reel Unwinding System : Unwinds the composite can material from a large roll.

- Glueing System : Applies adhesive to the composite can material to ensure proper bonding during forming.

- Folding and Heat Sealing System : Folds the composite can material into a cylindrical shape and seals the seam using heat.

- Online Fine Cutting : Ensures precise trimming of the can body to the desired dimensions.

- Labelling: Applies labels to the finished can body for branding and product information.

- Recutting: Performs any necessary recutting of the can body after labelling.

- Can Seaming : Seals the can lid onto the body using a specialised seaming process.

Key Features to Consider

-

- High-Speed Performance: Ensure the machinery can meet your production demands with efficient processing capabilities.

- Flexibility: Opt for machinery that handles various can sizes and designs, adapting to different market needs.

- Quality Control Mechanisms: Prioritize user-friendly interfaces with easy-to-use controls for smoother operation and minimal training time.

- User-Friendly Interface: Prioritize user-friendly interfaces with easy-to-use controls for smoother operation and minimal training time.

- Sodaltech understands the needs of composite can manufacturers. With a proven track record and a commitment to innovation, we offer high-performance composite can making machinery that incorporates advanced quality control systems and user-friendly interfaces.

What to Consider Before Investing

Before investing in composite can making machinery, it’s crucial to consider several factors:

-

- Market Research: Thoroughly research the demand for composite cans in your target market.

- Production Requirements: Determine the types and sizes of cans you plan to produce, ensuring the machine meets your output needs.

- Available Space: Consider the physical space required for installation and operation of the machinery.

- Budget: Factor in the initial machine purchase cost, potential additional equipment needs, and ongoing maintenance expenses.

- Return on Investment (ROI): Evaluate the projected production output and profitability to determine a realistic timeline for ROI.

For a reliable and efficient composite can making solution, consider partnering with Sodaltech.

Investing in Composite Can Production Line: A Long-Term Perspective

While the initial investment in composite can making machinery may seem significant, it’s crucial to consider the long-term benefits that contribute to a positive return on investment (ROI). These benefits go beyond simply increasing production capacity. Here’s a closer look at the key advantages:

Increased Production Capacity and Market Expansion: Composite can making machinery automates the production process, significantly boosting your output compared to manual or semi-automated methods. This allows you to meet higher customer demand and potentially expand your market share. By offering a wider range of composite can options, you can cater to new customer segments and diversify your product portfolio.

Improved Efficiency and Reduced Labour Costs: Automation streamlines the production process, minimizing reliance on manual labour. This translates to reduced labour costs and a more efficient operation. Additionally, consistent quality control systems integrated into the machinery help minimize errors and product waste, further enhancing overall efficiency.

Enhanced Product Quality and Customer Satisfaction: Modern composite can making machinery utilizes advanced technologies to ensure consistent and precise can formation, sealing, and finishing. This leads to high-quality, leak-proof cans that meet the strictest standards. Consistent product quality fosters customer satisfaction and loyalty, potentially increasing repeat business and brand reputation.

Environmental Benefits and Sustainability: Composite cans are a sustainable packaging solution compared to traditional metal cans. They are typically made from renewable and recyclable materials like paperboard, aluminium foil, and plastic film. By switching to a composite can production line, you can contribute to a more sustainable future by reducing your environmental footprint. Additionally, modern machinery often features energy-efficient technologies that minimize power consumption, further reducing your carbon footprint and potentially lowering utility costs.

Maintenance and Lifespan Considerations

Implement a proactive maintenance plan with regular checks, cleaning, lubrication, and part replacements to ensure optimal performance and lifespan.

The lifespan depends on maintenance and technology advancements. Consider budgeting for potential replacements to maintain a competitive edge.

Training and Safety

Proper operator training is essential for safe and efficient operations. Work with your supplier to provide comprehensive training on machine operation, maintenance, troubleshooting, and safety protocols. Prioritize safety by adhering to guidelines, providing personal protective equipment, and maintaining a clean workspace.

Investing in the Future

Investing in composite can making machinery is a strategic decision that can significantly benefit your business and contribute to a more sustainable future. By carefully considering the factors outlined in this blog post, you can make an informed choice and maximize the success of your investment.

Ready to explore the possibilities of composite can making?

Contact SODALTECH today!