- Home

- About Us

- Machinery

- Paper Cone Production Line

Automatic Paper Cone Plant

-

Automatic Paper Cone Making Machine with Online Drier

-

Automatic Paper Cone Finishing Machine (Twin Index)

Semi Automatic Paper Cone Plant

-

- Paper Tube & Core Production Line

- Composite Can Production Line

- Pulp Moulding Production Line

- Tableware Production Line

- Edge Protector Production Line

- Fibre Drum Production Line

- Square Drum Production Line

- Paper Cone Production Line

- Products

- Projects

- CSR

- Contact Us

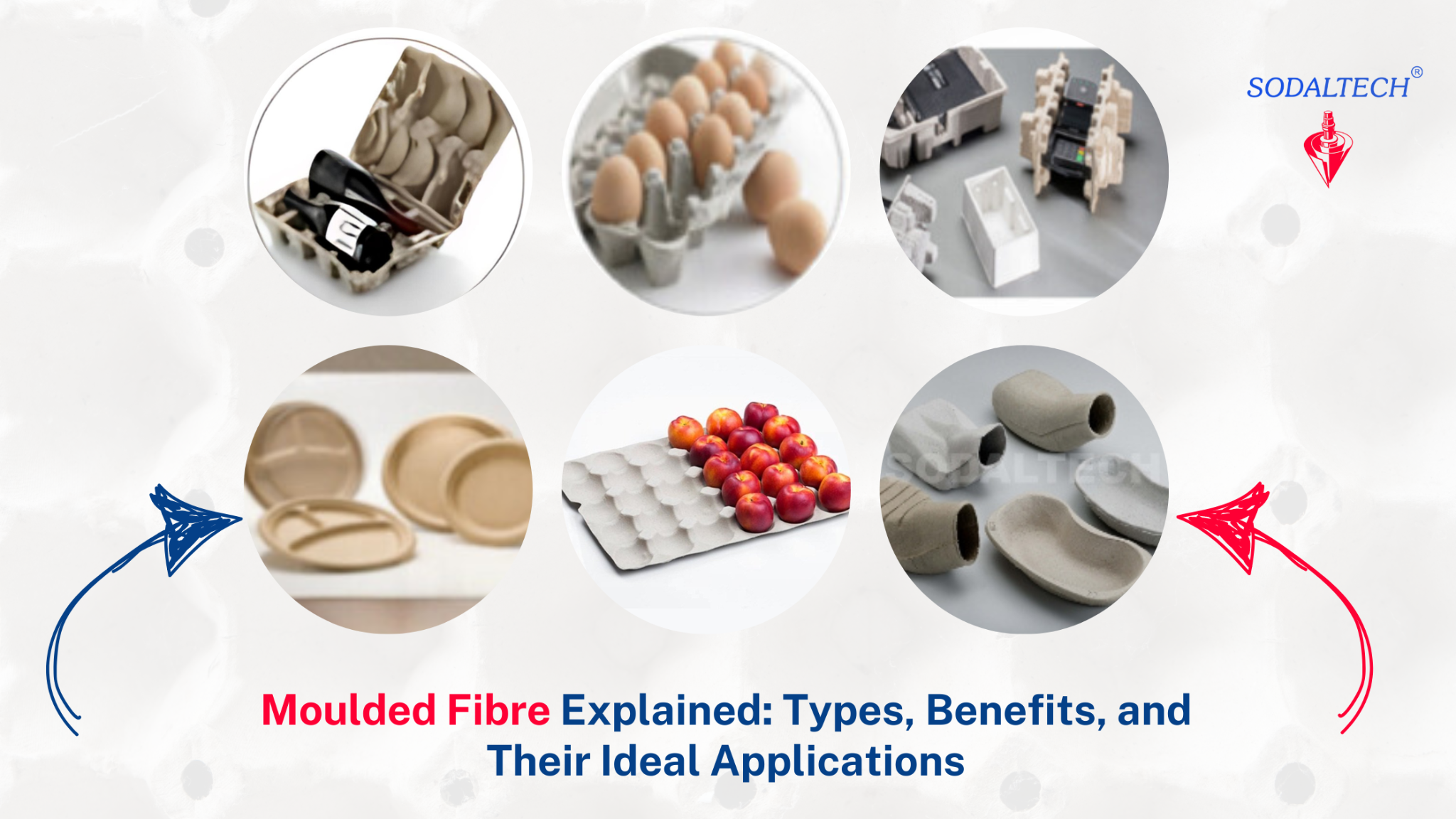

Moulded Fibre Explained: Types, Benefits, and Their Ideal Applications

Introduction

As the global push for sustainability grows, both businesses and consumers are increasingly seeking environmentally friendly materials that minimize their impact on the planet. One such material that has gained significant traction is moulded fibre (also known as moulded pulp). Made from recycled paper and other natural fibres, this highly adaptable and eco-friendly material offers an excellent balance between functionality and sustainability.

From moulded fibre egg trays and egg cartons to fruit and vegetable trays, moulded fibre provides versatile solutions for various industries. This blog will explore the different types of moulded pulp, each with unique properties and applications. Whether you’re seeking durable packaging or sustainable alternatives to plastic, this guide will provide valuable insights into how moulded fibre can meet your business needs.

By the end of this article, you’ll have a comprehensive understanding of moulded fibre types and their best uses—from moulded fibre egg trays to custom packaging solutions.

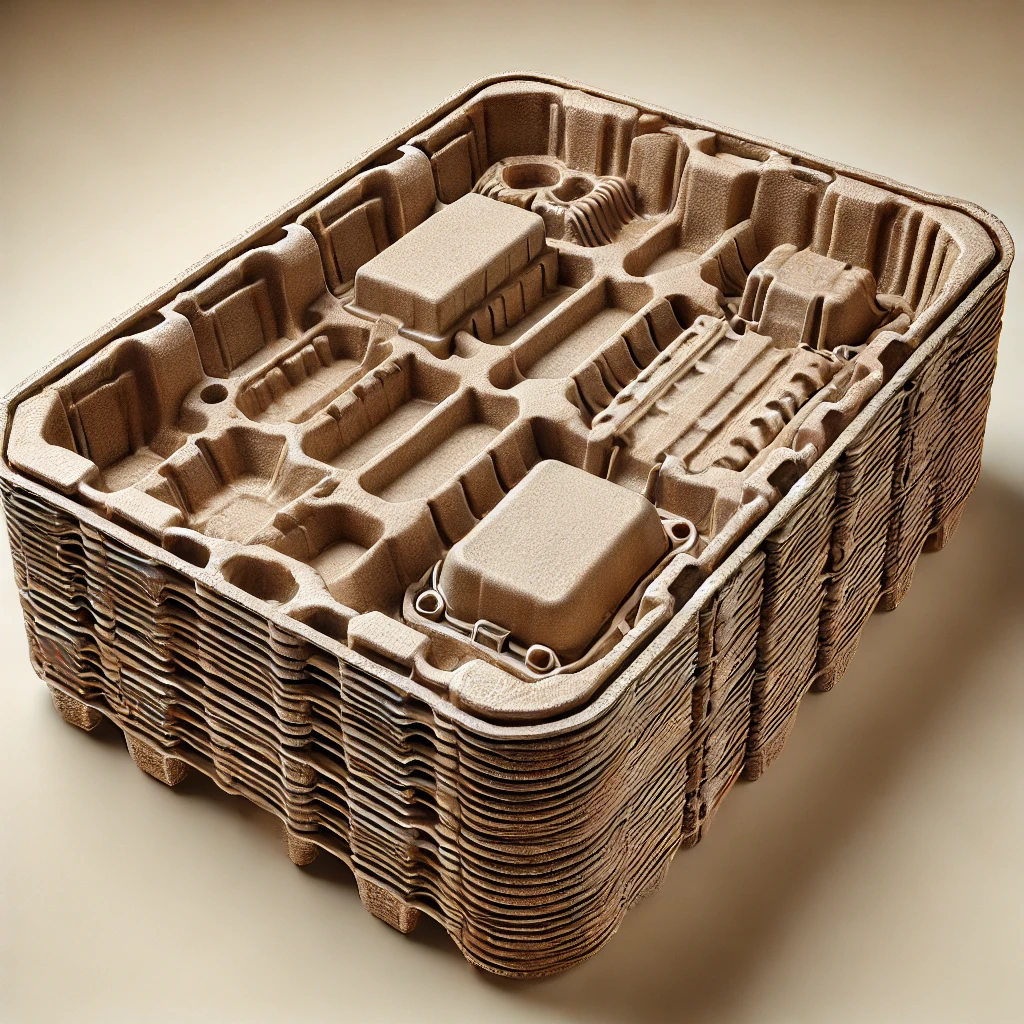

1. Thick-Walled Moulded Fibre

Thick-walled moulded fibre is known for its durability and strength. Made from recycled paper pulp, including kraft paper and cardboard, this material is dense and robust, making it ideal for protecting heavy or fragile items during transportation. It often features an unfinished surface on one side and a moderately finished surface on the other.

Best Applications:

- Protective Packaging: Thick-walled moulded fibre is commonly used to protect heavy electronics, automotive parts, and other items requiring strong shock absorption. Its rustic profile makes it ideal for edge protectors and other heavy-duty packaging solutions.

- Moulded Fibre Egg Trays and Egg Cartons: It is frequently utilized in the production of egg trays and cartons due to its excellent cushioning properties. They also maintain structural integrity in humid conditions, ensuring eggs are well-protected during transport and storage.

- Medical Sector: Thick-walled moulded fibre is also employed in the medical sector for packaging and protective applications, such as medical device casings and sterile packaging, where strength and impact resistance are crucial.

2. Transfer Moulded Fibre

Transfer moulded fibre is slightly thinner compared to thick-walled fibre and features a finer texture and smoother surface. The manufacturing process involves transferring the pulp from one mould to another, resulting in a polished finish on both sides.

Best Applications:

- Fruit & Vegetable Trays: With its smooth finish, transfer moulded fibre is an ideal choice for fruit and vegetable trays. It provides excellent protection for produce while enhancing visual appeal and ensuring ventilation.

- Consumer Packaging: This material is also well-suited for packaging cosmetics and electronic devices, where both appearance and protection are essential.

3. Thermoformed Moulded Fibre

Thermoformed moulded fibre is created using heat and pressure to produce a thinner, more refined product. This lightweight material offers high precision in moulding, making it ideal for applications that require both aesthetics and performance.

Best Applications:

- Food Service Products: Thermoformed moulded fibre is widely used in the food industry for disposable plates, trays, clamshell boxes, and other containers. Its lightweight design facilitates handling, while the smooth finish enhances product appeal.

- Retail Packaging: Lightweight products like cosmetics and accessories benefit from thermoformed fibre packaging, which combines sustainability with an attractive presentation.

4. Processed Moulded Fibre

Processed moulded fibre undergoes additional treatments to enhance its properties, such as moisture resistance, strength, and surface finish. This makes it suitable for applications requiring greater durability than standard moulded fibre.

Best Applications:

- Food Packaging: Processed moulded fibre is ideal for takeout containers and trays that must withstand moisture and grease, making it perfect for the food industry.

- Industrial Applications: This type of fibre is also used for packaging in industrial sectors that require customized, durable solutions.

- Disposable Medical Products: Processed moulded fibre can also be used for medical products like disposable urinals, bedpan liners, and commode pans. The trend towards disposable items in the medical industry helps reduce cross-infection risks while offering eco-friendly and cost-effective solutions.

Conclusion

Moulded fibre is a versatile and sustainable material that has become essential in various industries, from packaging to food service and medical applications. With several different types of moulded fibre available, it can meet a wide range of needs—from moulded fibre egg trays to high-end custom packaging.

As the demand for sustainable products continues to grow, partnering with a trusted moulded fibre machinery manufacturer in India, like Sodaltech, can help your business stay ahead of the curve. Incorporating moulded fibre into your operations not only contributes to environmental conservation but also enhances your brand’s reputation as a leader in sustainability.

Contact Sodaltech today to explore how our advanced moulded fibre machinery can help you meet the growing demand for moulded fibre pulp products and drive your business toward a greener future.

ENQUIRY FORM SODALTECH

Don't hesitate to contact us if you would like to know more about what we can do for you.