- Home

- About Us

- Machinery

- Paper Cone Production Line

Automatic Paper Cone Plant

-

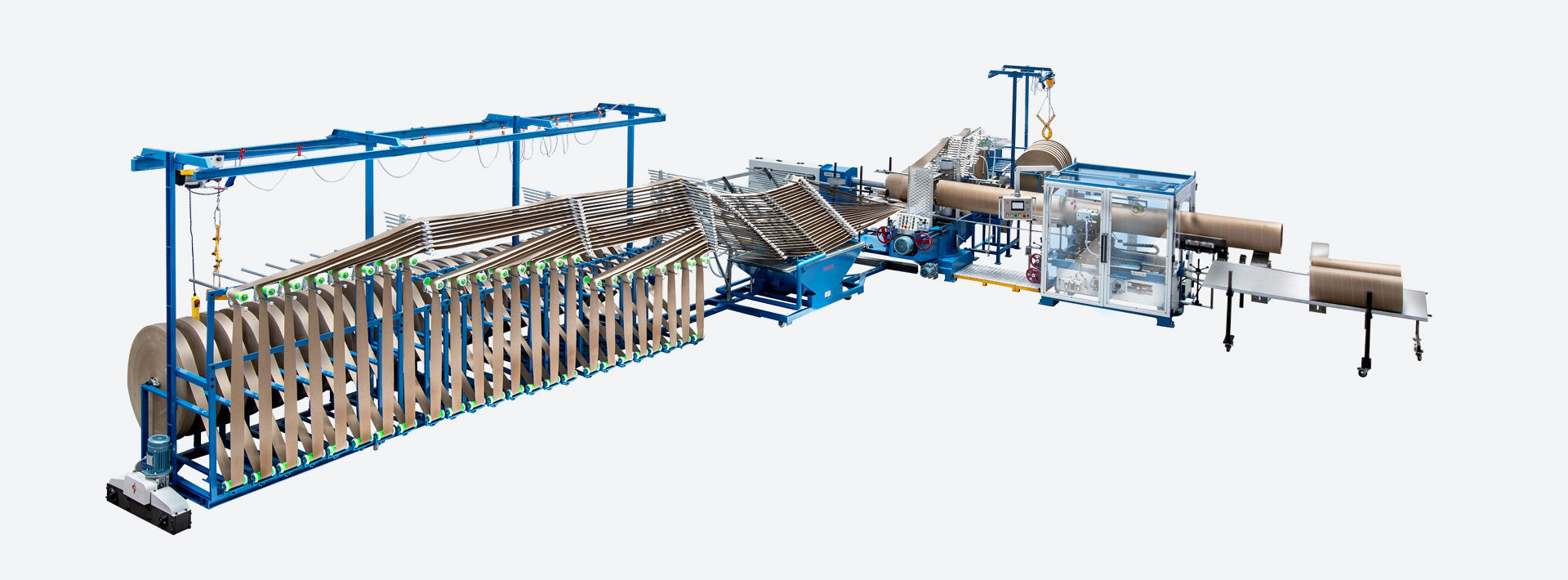

Automatic Paper Cone Making Machine with Online Drier

-

Automatic Paper Cone Finishing Machine (Twin Index)

Semi Automatic Paper Cone Plant

-

- Paper Tube & Core Production Line

- Composite Can Production Line

- Pulp Moulding Production Line

- Tableware Production Line

- Edge Protector Production Line

- Fibre Drum Production Line

- Square Drum Production Line

- Paper Cone Production Line

- Products

- Projects

- CSR

- Contact Us

The Pulp Moulding Machinery Market is Set to Reach New Heights by 2030

The pulp moulding machinery market is set for impressive growth by 2030, driven by the increasing demand for sustainable packaging solutions. Pulp moulding, also known as fiber moulding or pulp thermoforming, transforms waste paper and pulp into diverse protective and consumer packaging materials.

This eco-friendly and cost-effective method has gained popularity in industries such as food and beverage, electronics, and healthcare, driving the demand for pulp moulding machinery.

Understanding the Pulp Moulding Machinery Market

The global pulp moulding machinery market is highly competitive, with leading companies continuously innovating to capture market share. This competitiveness drives technological advancements and enhances product offerings, meeting the evolving needs of various industries.

One of the key factors driving the demand for pulp moulding machinery is the increasing adoption of sustainable packaging solutions. With growing environmental concerns, industries across the globe are shifting towards eco-friendly alternatives. Pulp moulded products, made from recycled materials, offer a sustainable and biodegradable packaging solution.

Market Size and Growth Rate

According to recent market research, the global pulp moulding machinery market is projected to reach $1.03 billion by 2028, expanding at a CAGR of around 6%. This growth is driven by several factors:

Firstly, the increasing adoption of sustainable packaging solutions is driving the demand for pulp moulding machinery. As more industries recognize the importance of reducing their environmental footprint, the demand for eco-friendly packaging materials is on the rise.

Secondly, the versatility of pulp moulding machinery makes it an attractive choice for manufacturers worldwide.

These machines can produce a wide range of products, including trays, containers, and protective packaging, offering flexibility to meet diverse market demands.

Regional Analysis of the Pulp Moulding Machinery Market

The pulp moulding machinery market is geographically segmented into North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. Currently, Asia Pacific dominates the market, accounting for the largest market share.

This can be attributed to the presence of key market players in the region, along with the rising demand for sustainable packaging solutions in countries like China and India. The rapid industrialization and urbanization in these countries have led to an increased need for efficient and eco-friendly packaging solutions.

However, other regions are also witnessing significant growth in the pulp moulding machinery market. In North America and Europe, the demand for sustainable packaging materials is driven by stringent regulations regarding plastic waste and a growing awareness of environmental conservation.

In Latin America, the Middle East and Africa, there is a rising focus on sustainable development, leading to an increased demand for eco-friendly packaging solutions. This, in turn, is fueling the growth of the pulp moulding machinery market in these regions.

Technological Advancements in Pulp Moulding Machinery

Technological advancements have played a crucial role in the development of pulp moulding machinery. Innovative features and automation have improved the efficiency and productivity of these machines, making them more appealing to manufacturers.

One of the significant advancements in pulp moulding machinery is the integration of cutting-edge materials that enhance the durability and performance of the equipment., increasing the lifespan of the machinery and reducing maintenance costs over time.

Innovations in Pulp Moulding Machinery

Companies are constantly striving to enhance their machinery by introducing new features and functionalities. Some key innovations in the pulp moulding machinery market include:

- Advanced control systems that provide real-time monitoring and adjustments for improved quality assurance.

- Energy-efficient technologies that reduce power consumption and contribute to environmental sustainability.

- Introduction of modular designs that allow for easier customization and scalability based on production needs.

Impact of Technology on Market Growth

The technological advancements in pulp moulding machinery have greatly influenced market growth. These innovations have not only improved efficiency and product quality but also reduced production costs. As a result, more businesses are inclined toward adopting pulp moulding machinery, contributing to the overall market expansion.

Furthermore, the integration of remote access and diagnostics capabilities in modern pulp moulding machinery has revolutionized maintenance practices. Manufacturers can now remotely monitor machine performance, identify potential issues, and even conduct predictive maintenance, minimizing downtime and maximizing operational efficiency.

Market Dynamics of the Pulp Moulding Machinery Industry

Several factors drive the growth and development of the pulp moulding machinery industry, while others pose challenges to market players.

The pulp moulding machinery industry is a dynamic sector that is heavily influenced by various market drivers and restraints. These factors play a crucial role in shaping the industry landscape and determining the success of market players.

Market Drivers, Opportunities and Challenges

The key market drivers include:

- Growing environmental concerns and regulations banning the use of single-use plastics.

- Increasing demand for biodegradable and sustainable packaging solutions.

- Rising investments in research and development activities focused on pulp moulding technology.

These drivers create a conducive environment for the growth of the pulp moulding machinery industry, driving innovation and market expansion.

The pulp moulding machinery market offers significant opportunities for both existing players and new entrants. The increasing demand for sustainable packaging solutions presents a vast market potential.

Despite the promising opportunities, market players face several challenges that need to be addressed to ensure sustainable growth and success in the industry. These challenges include:

- Intense market competition from established players.

- Constantly evolving market dynamics and customer preferences.

- Adherence to stringent environmental regulations and sustainability standards.

Successfully navigating these opportunities and challenges is essential for companies operating in the pulp moulding machinery industry to thrive and stay ahead in the competitive market landscape.

Future Projections for the Pulp Moulding Machinery Market

The pulp moulding machinery market is expected to witness several trends in the coming years, driven by various factors.

Market Trends and Predictions

Some of the major trends that are likely to shape the pulp moulding machinery market include:

- Increasing adoption of fully automated machinery to enhance productivity and reduce labour costs.

- Growing focus on product customization and flexibility to cater to diverse customer requirements.

- Rising investments in research and development activities to develop advanced moulding technologies.

Impact of Global Economy on the Market

The global economy plays a crucial role in the growth and development of the pulp moulding machinery market. Economic factors, such as GDP growth, disposable income levels, and industrialization rates, can directly influence market dynamics.

The increasing demand for sustainable packaging solutions and the rising focus on eco-friendly manufacturing processes are expected to drive market growth. However, economic fluctuations and trade policies may pose challenges to market players.

Environmental Impact and Sustainability of Pulp Moulding Machinery

One of the key advantages of pulp moulding machinery is its positive environmental impact and contribution to sustainability.

Role of Pulp Moulding Machinery in Sustainability

Pulp moulding machinery facilitates the production of biodegradable and compostable products, reducing the dependence on non-renewable resources and minimizing waste generation. These products can be recycled or composted, offering a sustainable alternative to single-use plastics.

Furthermore, the energy-efficient technologies incorporated in modern paper pulp moulding machine help minimize carbon emissions and conserve natural resources.

Environmental Regulations and Their Impact on the Market

Stringent environmental regulations and policies implemented by governments worldwide have accelerated the adoption of paper pulp moulding machine. The ban on single-use plastics and the emphasis on sustainable manufacturing processes have created a favorable market environment for pulp moulding machinery manufacturers.

Conclusion

The pulp moulding machinery market is set to reach new heights by 2030, driven by the increasing demand for sustainable packaging solutions and the advancements in technology. This market offers significant opportunities for both existing players and new entrants, while also presenting challenges related to capital investment and regulatory compliance.

The future of the market will be characterized by trends such as automation, customization, and research and development activities.

Overall, the Paper pulp moulding machine market is on track for remarkable growth in the coming years.

Sodaltech, renowned for excellence in pulp moulding machinery, remains committed to innovation and quality, keeping us at the forefront as one of the best Pulp Moulding Machinery manufacturers!

ENQUIRY FORM SODALTECH

Don't hesitate to contact us if you would like to know more about what we can do for you.