- Home

- About Us

- Machinery

- Paper Cone Production Line

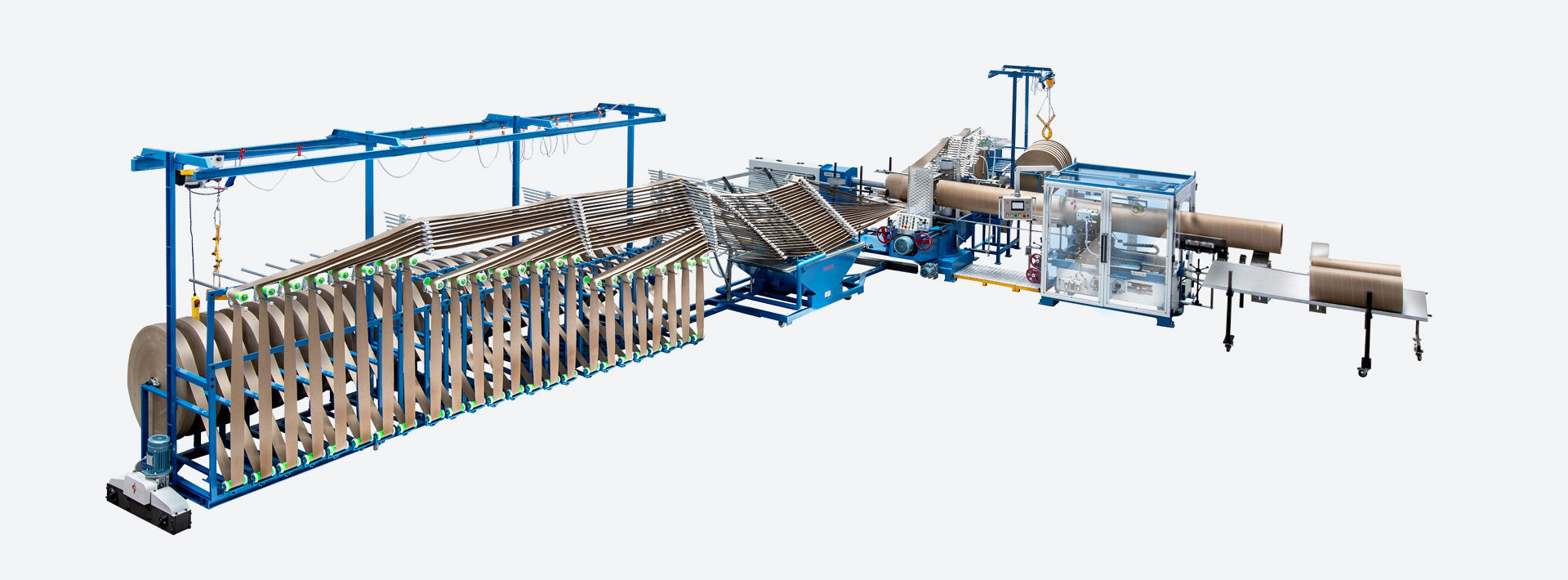

Automatic Paper Cone Plant

-

Automatic Paper Cone Making Machine with Online Drier

-

Automatic Paper Cone Finishing Machine (Twin Index)

Semi Automatic Paper Cone Plant

-

- Paper Tube & Core Production Line

- Composite Can Production Line

- Pulp Moulding Production Line

- Tableware Production Line

- Edge Protector Production Line

- Fibre Drum Production Line

- Square Drum Production Line

- Paper Cone Production Line

- Products

- Projects

- CSR

- Contact Us

Top 5 Emerging Trends in Pulp Molding Packaging for 2025

As sustainability becomes a crucial focus for consumers and businesses alike, pulp molding packaging is emerging as a frontrunner in eco-friendly solutions.

Pulp molding is a process that transforms recycled paper, cardboard, and other fiber materials into protective packaging products.

As we look ahead to 2025, several exciting trends are set to reshape the landscape of pulp molding packaging.

In this article we will explore the top five emerging trends that are likely to dominate the industry in the coming years.

1. Increased Use of Biodegradable Coatings

One of the most significant trends in pulp molding packaging is the growing adoption of biodegradable coatings. These coatings provide enhanced resistance to water, grease, and other substances while maintaining the eco-friendliness of the packaging. As consumers increasingly prioritize sustainable choices, brands are eager to replace traditional plastic-lined containers with fully compostable options.

Biodegradable coatings not only improve the functionality of pulp molded packaging but also align with the values of environmentally conscious consumers. This shift allows brands to offer products that are both high-quality and sustainable, ultimately boosting their market appeal.

2. Integration of Smart Packaging Features

The integration of smart packaging features into pulp molding is another emerging trend. Technologies such as QR codes, RFID tags, and NFC chips are being incorporated to enhance the functionality of packaging. These smart features enable traceability and improve inventory management while also providing engaging experiences for consumers.

For instance, a simple scan of a QR code can provide information about a product’s origin, freshness, and even suggested uses. This trend is particularly valuable in industries like food and pharmaceuticals, where tracking freshness and authenticity is critical. By adopting smart packaging, companies can not only meet consumer demands for transparency but also streamline operations and improve supply chain efficiency.

3. Focus on Customization and Branding

As competition intensifies, brands are increasingly seeking ways to differentiate themselves. Custom molds and designs in pulp molding packaging are becoming more accessible and cost-effective, allowing businesses to create unique shapes, textures, and colors that reflect their brand identity.

This trend towards customization helps products stand out on the shelves, fostering stronger brand recognition and loyalty among consumers. In an era where consumer choices are abundant, personalized packaging can be a game-changer, driving engagement and sales.

4. Lightweight and Cost-Effective Solutions

With rising material and shipping costs, there is a pressing demand for lightweight packaging solutions. Advances in material science are enabling pulp molding to achieve a balance between strength and weight, resulting in packaging that is both protective and easy to handle.

Lightweight pulp molded packaging not only reduces transportation costs and carbon footprints but also improves the overall user experience. This trend is beneficial for companies looking to enhance their sustainability credentials while simultaneously cutting logistics expenses, leading to greater efficiency across the supply chain.

5. Expansion into New Markets Beyond Food Packaging

While pulp molding has traditionally been associated with food packaging, its applications are expanding into new markets, including electronics, cosmetics, and other fragile items. As businesses move away from plastic foams and bubble wraps, pulp molded packaging is emerging as a versatile, eco-friendly alternative.

This trend opens up exciting opportunities for manufacturers to innovate and cater to a broader range of industries. By offering sustainable packaging solutions for diverse products, businesses can support their sustainability goals while appealing to a wider customer base.

Conclusion:

The trends shaping pulp molding packaging for 2025 highlight a significant shift towards sustainability, innovation, and customization. As biodegradable coatings, smart features, and unique designs become more prevalent, businesses that embrace these changes will be well-positioned to meet the evolving needs of consumers.

The move towards lightweight solutions and the expansion into new markets further solidify pulp molding as a key player in the packaging industry.

At Sodaltech, we continuously innovate to align with these emerging trends, ensuring that our pulp molding machinery meets the evolving demands of industries worldwide. With our commitment to quality and sustainability, we aim to empower businesses to thrive in a greener future.

ENQUIRY FORM SODALTECH

Don't hesitate to contact us if you would like to know more about what we can do for you.