- Home

- About Us

- Machinery

- Paper Cone Production Line

Automatic Paper Cone Plant

-

Automatic Paper Cone Making Machine with Online Drier

-

Automatic Paper Cone Finishing Machine (Twin Index)

Semi Automatic Paper Cone Plant

-

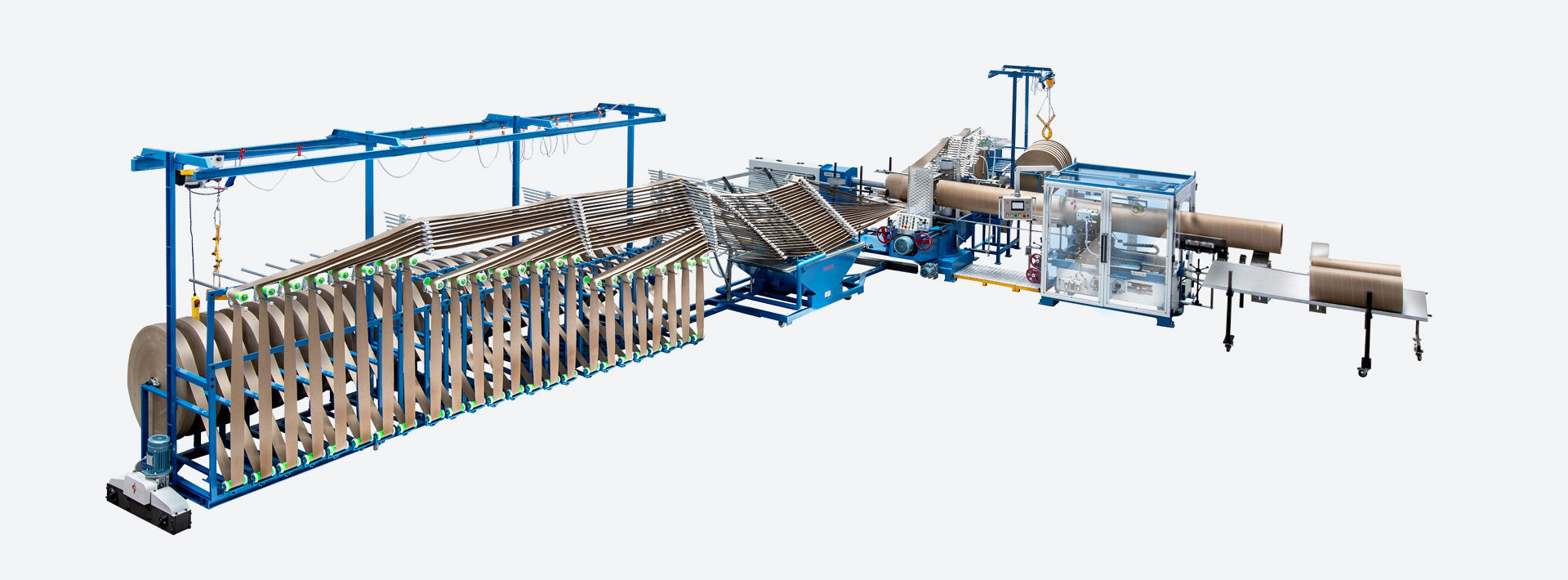

- Paper Tube & Core Production Line

- Composite Can Production Line

- Pulp Moulding Production Line

- Tableware Production Line

- Edge Protector Production Line

- Fibre Drum Production Line

- Square Drum Production Line

- Paper Cone Production Line

- Products

- Projects

- CSR

- Contact Us

What Raw Materials Does An Egg Tray Making Machine Use?

Egg tray making machines are at the heart of egg packaging production, transforming raw materials into sturdy containers that safeguard eggs during transportation and storage. Understanding the essential raw materials required is crucial for producing high-quality egg trays efficiently and sustainably.

In this article, we will look into the world of egg tray making machines, exploring their pivotal role in egg packaging, the essential raw materials for egg tray production, and how they contribute to eco-friendly packaging solutions.

The Importance of Egg Packaging

Egg packaging is vital for several reasons. Firstly, it protects eggs from cracks and breakages during transportation. The fragile nature of eggs makes them susceptible to damage, but proper packaging minimizes such risks. Secondly, packaging provides a barrier against moisture and external contaminants, ensuring the freshness and safety of eggs. Lastly, egg packaging facilitates easy handling, storage, and display, making it convenient for both producers and consumers.

How Egg Carton and Tray Making Machines Work

The working principle of these machines involves a series of steps. It starts with the collection and pulping of scrap paper or other suitable raw materials. The pulping system breaks down the materials into a fine pulp, which is then molded into the desired shape using the molding system. After molding, the products are dried using the drying system to achieve the desired strength and durability. Finally, the packaging system ensures the proper arrangement and packaging of the finished egg cartons or trays.

Common Raw Materials Used in Egg Tray Making Machines

Egg tray making machines utilize a range of raw materials to produce high-quality egg trays. When it comes to the production of egg trays, the selection of raw materials plays a crucial role in determining the quality and efficiency of the end product. Each raw material contributes unique properties that are essential for the functionality and durability of the egg trays.

Paper Waste:

Paper waste is a widely available and cost-effective raw material for egg tray production. Common sources of paper waste include old newspapers, magazines, used office paper, cardboard boxes, and other paper products. Recycling paper waste not only helps reduce environmental pollution but also conserves natural resources by decreasing the need for virgin paper. By diverting paper waste from landfills, manufacturers contribute to a more sustainable waste management system and reduce the overall environmental impact. This recycling process also supports the creation of new products without depleting additional natural resources. By integrating paper waste into the production process, egg tray manufacturers can produce high-quality, eco-friendly packaging solutions that benefit both the environment and the economy.

Water:

Water is an essential element in the egg tray making process. It not only helps in the pulping of paper waste but also aids in the molding and drying stages. The appropriate amount of water is required to achieve the desired consistency of the pulp and to facilitate the formation of egg trays.

Proper water management is crucial in the production of egg trays to ensure the efficient utilization of resources and to maintain the structural integrity of the final product. The controlled use of water in each stage of the manufacturing process is essential for achieving consistent quality and minimizing waste.

pH Conditioner:

For the best paper quality during the pulping process, the pH of the pulp combination must be maintained. An additive called a pH conditioner is used to keep the pH at or below 5, which is the perfect range for pulp making. Usually added as flakes, the pH conditioner is added to the pulp combination in amounts ranging from 1% to 3%. This chemical aids in regulating the pulp’s acidity or alkalinity, which can impact the finished paper product’s strength, brightness, and other characteristics. The pH conditioner helps to guarantee that the pulping process proceeds smoothly and that the finished product satisfies quality standards by regulating the pH of the pulp mixture.

Moisture Barrier:

A moisture barrier is essential for manufacturing moisture-proof egg trays. When manufacturing egg trays, this additive is usually added to the pulp mixture in amounts between 3% and 4%. Without this additive, paper goods would be more prone to moisture degradation. By adding a moisture barrier to the pulp mixture, manufacturers can create high-quality egg trays that satisfy consumer demands while simultaneously cutting waste and environmental impact .Overall, the moisture barrier is a critical component in egg tray production, improving durability and extending the lifespan of paper products.

Sizing Agent:

A sizing agent is a vital component in egg tray manufacturing, as it enhances the strength and water resistance of the final product. This additive is typically added to the pulp mixture for wet-end sizing, where it forms a protective film on the surface of the paper fibers. This helps to prevent water from penetrating the paper, making it more resistant to moisture and improving its durability. By adding a sizing agent to the pulp mixture, egg tray manufacturers can produce paper products that are suitable for a wide range of applications where water resistance is important. Overall, the sizing agent is a crucial additive that helps to enhance the quality and performance of the egg trays and cartons.

Factors To Consider While Sourcing Raw Materials:

When sourcing raw materials for egg tray making, several factors need to be considered to ensure the quality and efficiency of production. Here are some key factors:

Quality of Waste Paper:

- Make sure there are no impurities in the waste paper, such as metals, plastics, or other non-paper materials.

- Stronger and more resilient trays will be made from clean, high-quality waste paper.

Availability and Consistency:

- Develop partnerships with several suppliers to reduce the risk of supply shortages.

- Ensure a consistent and dependable supply of waste paper to prevent production interruptions.

Cost:

- Evaluate the cost of waste paper from different suppliers and consider transportation costs.

- Opt for suppliers that offer competitive pricing without compromising quality.

Additives:

- Identify the necessary additives like starch, alum, or rosin required to enhance the tray’s strength and durability.

- Make sure these additives are suitable with the production process and easily accessible.

Environmental Impact:

- Choose suppliers that follow environmentally friendly practices in waste paper collection and processing.

- Consider the carbon footprint associated with the transportation of raw materials.

Regulatory Compliance:

- Ensure that the sourced waste paper complies with local and international regulations regarding recycling and waste management.

- Verify that the suppliers adhere to relevant environmental and safety standards.

Transportation and Storage:

- Consider the logistics involved in transporting raw materials from suppliers to the manufacturing facility.

- Ensure proper storage conditions to maintain the quality of waste paper and additives.

The Importance of Raw Materials in Egg Tray Production

The quality of raw materials is crucial in egg tray production, impacting both the strength and durability of the final product. Using high-quality, clean paper waste ensures the trays are sturdy and reliable, protecting eggs during transportation and storage. The right raw materials also influence the production process efficiency and the environmental footprint of the trays. Proper selection and handling of raw materials lead to consistent product quality, minimizing waste and optimizing resource use. Ultimately, the choice of raw materials plays a significant role in producing eco-friendly, high-performing egg trays.

Environmental Impact of Raw Materials

The environmental impact of raw materials in egg tray production is significant. Utilizing recycled paper waste reduces the need for virgin paper, conserving natural resources and lowering carbon emissions. This practice also helps minimize landfill waste, promoting a circular economy. Choosing sustainable raw materials, such as biodegradable additives, further reduces the environmental footprint. By prioritizing eco-friendly raw materials, manufacturers can produce egg trays that not only protect eggs but also support environmental conservation efforts. This approach aligns with global sustainability goals, contributing to a greener and more responsible manufacturing process.

Furthermore,opting for locally sourced materials can reduce transportation emissions and support local economies.

Conclusion:

Egg tray making machines exemplify the efficient and eco-friendly recycling of waste paper into high quality egg trays. By utilizing waste paper, these machines not only help in managing paper waste but also contribute to environmental conservation by reducing the need for virgin paper, thereby saving trees and lowering carbon footprints.

This method underscores the importance of recycling and innovative waste management solutions in today’s sustainability-driven world.

Overall, egg tray making machines represent a critical blend of environmental responsibility and industrial ingenuity, offering a practical solution to waste management and resource conservation.

Looking for the best egg tray machine?

Sodaltech is here to help you!

ENQUIRY FORM SODALTECH

Don't hesitate to contact us if you would like to know more about what we can do for you.