- Home

- About Us

- Machinery

- Paper Cone Production Line

Automatic Paper Cone Plant

-

Automatic Paper Cone Making Machine with Online Drier

-

Automatic Paper Cone Finishing Machine (Twin Index)

Semi Automatic Paper Cone Plant

-

- Paper Tube & Core Production Line

- Composite Can Production Line

- Pulp Moulding Production Line

- Tableware Production Line

- Edge Protector Production Line

- Fibre Drum Production Line

- Square Drum Production Line

- Paper Cone Production Line

- Products

- Projects

- CSR

- Contact Us

- Home

- Machinery

- Composite Can Production Line

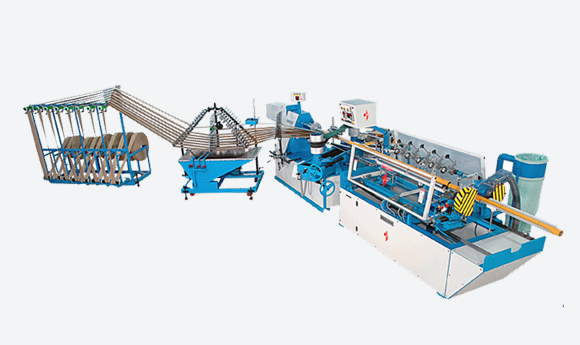

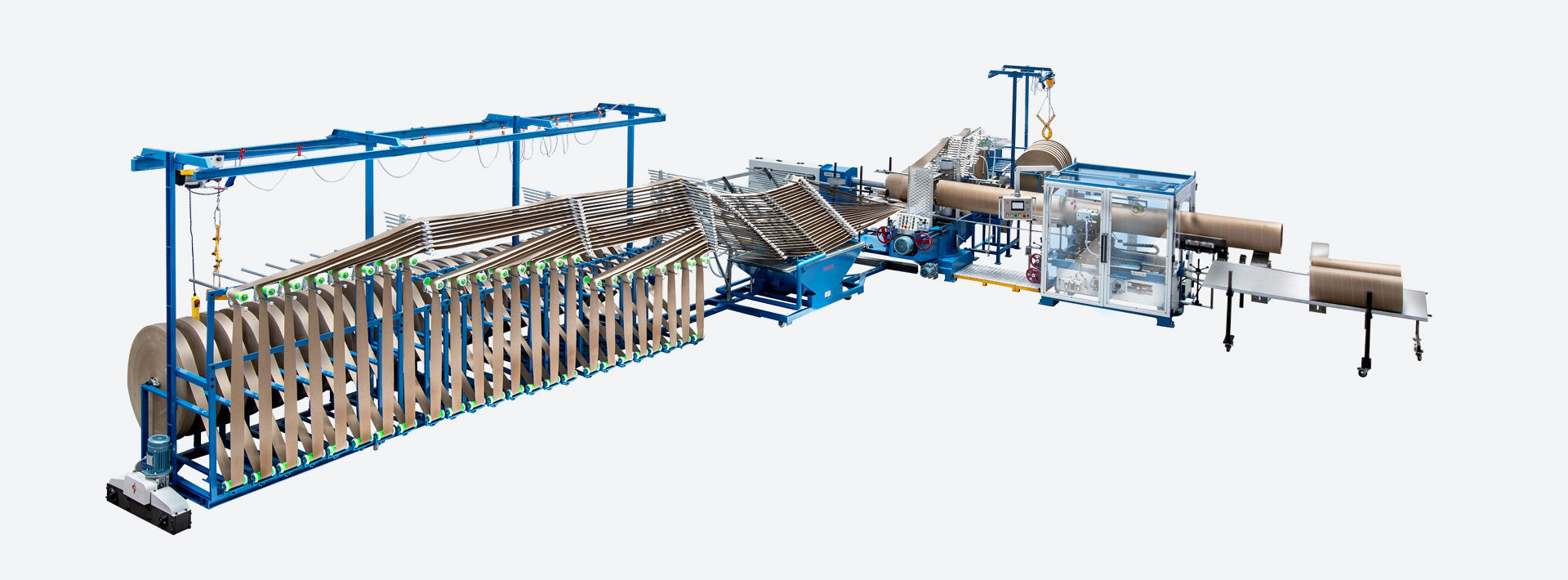

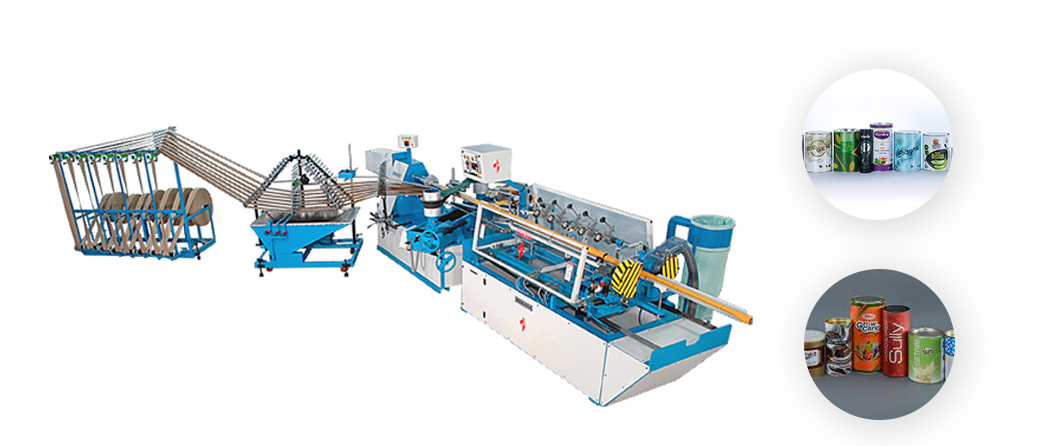

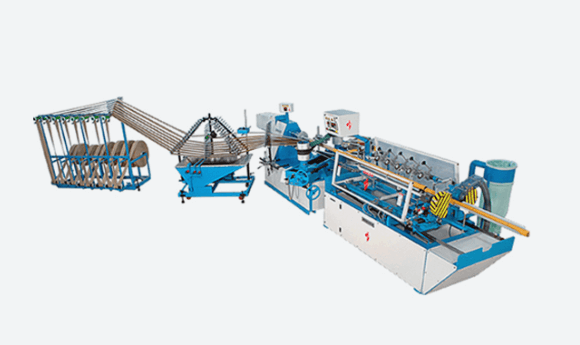

- Composite Can Machine

Key Features

The Composite Can Making Plant is suitable to make Composite Cans for packaging of detergents, liquor bottles, automobile components, engineering goods, laminated cans for packaging of potato wafers, fruit drink, etc. These composite cans are eco-friendly as they are easily disposable and recyclable.

The can body maker is fitted with a folding and heat sealing equipment to heat seal inner aluminium foil layer for leak proof cans.

The key feature of this production line is its high performance with low maintenance cost. The composite cans making machinery comes with other optional equipment for producing composite cans, which include labelling machine, can flanger and can seamer.

The composite can production line facilitates easy interchangeability of toolings for various sizes of cans.

Salient Features

- Output : 30,000 cans per day of 24 hours operation depending upon the sizes

- Minimum inner diameter of the can : 25 mm

- Maximum inner diameter of the can : 100 mm

- Maximum height of the can : 525 mm

- Maximum Wall thickness : 3 mm

Machinery Videos

ENQUIRY FORM SODALTECH

Don't hesitate to contact us if you would like to know more about what we can do for you.