- Home

- About Us

- Machinery

- Paper Cone Production Line

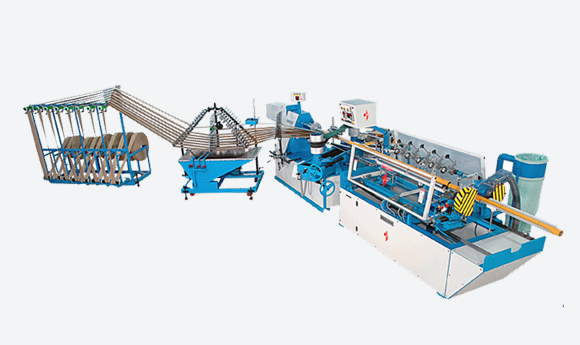

Automatic Paper Cone Plant

-

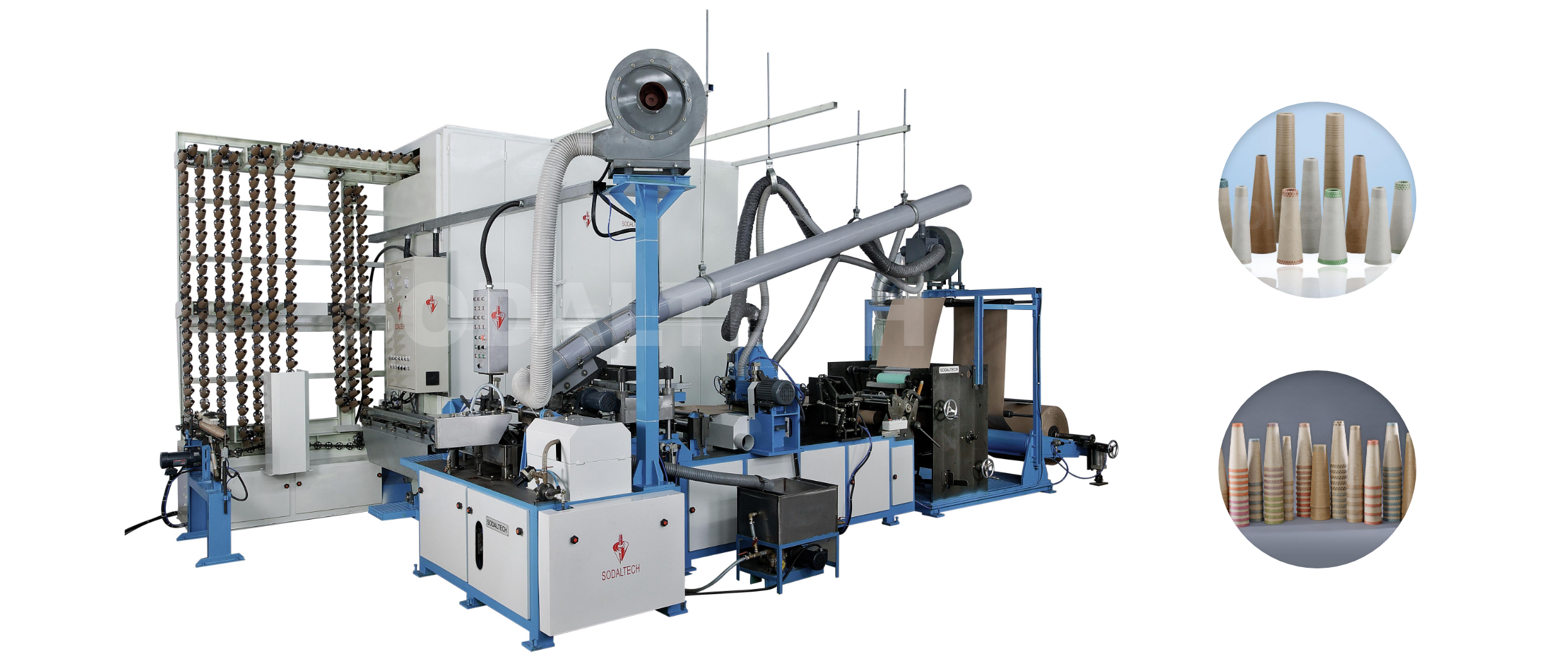

Automatic Paper Cone Making Machine with Online Drier

-

Automatic Paper Cone Finishing Machine (Twin Index)

Semi Automatic Paper Cone Plant

-

- Paper Tube & Core Production Line

- Composite Can Production Line

- Pulp Moulding Production Line

- Tableware Production Line

- Edge Protector Production Line

- Fibre Drum Production Line

- Square Drum Production Line

- Paper Cone Production Line

- Products

- Projects

- CSR

- Contact Us

- Home

- Machinery

- Paper Cone Production Line

- Automatic Paper Cone Making Machine with Online Drier

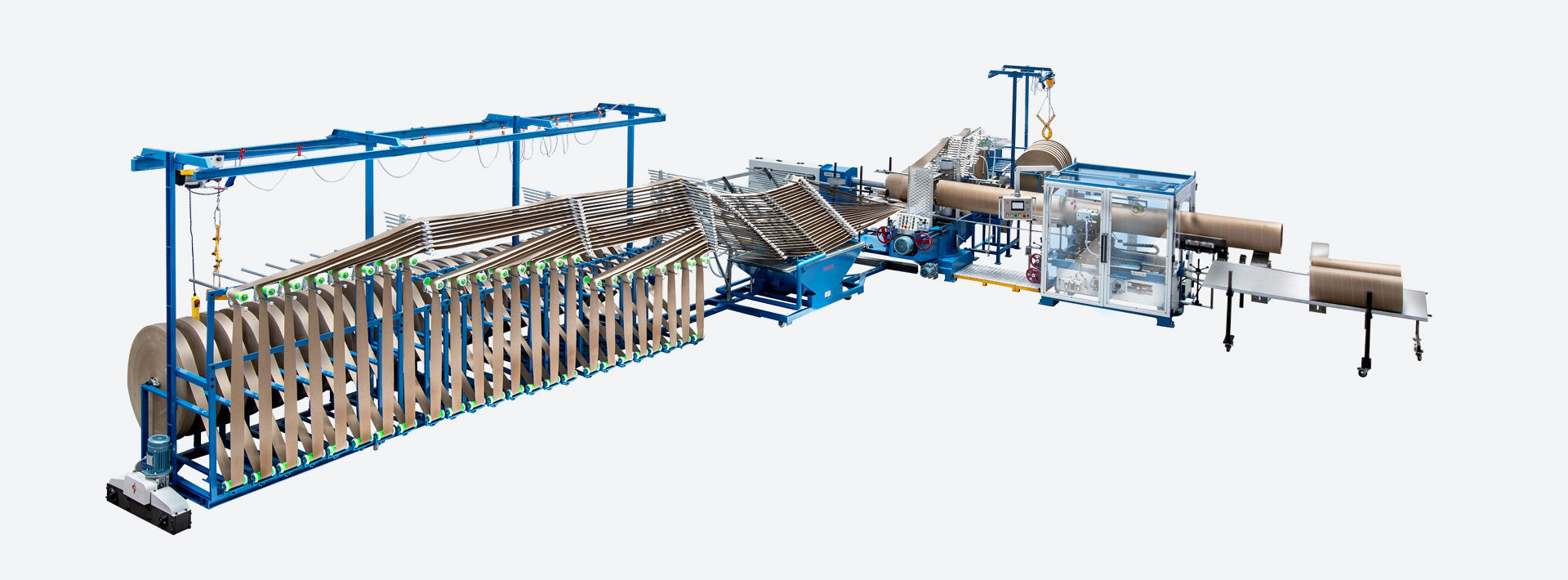

The fully automatic paper cone production line from Sodaltech is engineered for seamless, efficient manufacturing of textile paper cones, an essential component for the spinning industry. Designed for high efficiency and precision, this production line is trusted by customers across the globe for its reliable performance.

Key Features

- Versatile Taper Options: Produces cones with tapers like 5°57′, 4°20′, and 3°30′ using suitable tooling.

- Adjustable Cone Length: Wound cone lengths range from 170 mm to 240 mm.

- High Efficiency: Peak output of up to 50 cones per minute.

- Precision Printing: Rotary Flexographic Printer for accurate top and bottom color patterns.

- Advanced Automation: Automatic feeding, grinding (inside and outside), and cone transport to the drier.

- Servo-Driven Accuracy: Winding station with programmable spindle speed for optimal performance.

- Quick Setup: Pattern cutting knife unit minimizes setup time between cone sizes.

Textile Paper

Cone Drier

The Sodaltech Automatic Online Conveyorised Paper Cone Drier Model CD50K (E) is designed to complement the winding machine, delivering uniformly dried cones with unmatched efficiency.

Key Features:The Drier is fully automatic, ensuring uniform drying of cones.

- Heating Source — Gas, Steam, Electric, Coal/Wood fired with suitable heat exchangers.

- Thermostat controlled temperature and blower with efficient air circulation for even drying.

- Automatic delivery of dried cones.

- Automatic cone counting and nesting

Technical Features :

- Well insulated doors and metal enclosures for energy saving

- Automatic Temperature control

- Safety device for overload prevention

- Provision to operate at variable speeds

- Auto Control equipment for Chain Conveyor tension

- Suitable Drive motor with control panel

- Ejection device to transfer nested cones to finishing process

- Delivery conveyor for dried cones with automatic nesting of cones

Specifications:

Connected load :

- Heaters (Electrical Model): 45 KW

- Motor Drives and Fan Blower: 4.07 KW

- Machine dimensions: 6.5m (L) x 1.7m (W) x 3.7m (H)

- Drier working temperature: 70°C to 90°C, based on site conditions.

Machine Dimensions :

- 6.5 metres length x 1.7 metres width x 3.7 metres height (approx.)

- Drier working temperature will be 70 Deg C to 90 Deg C depending on the site working

conditions

Machinery Videos

Exporting to more than 70 Countries

Why Choose Sodaltech

- Efficient Production Process: Tailored to meet various cone manufacturing needs.

- Sustainability: Supports recycling, reducing waste and reliance on virgin raw materials.

- Easy to Operate: User-friendly design ensures smooth functionality.

- Customizable Features: Adjustable for cone sizes, shapes, and additional requirements.

- Cost-Effective Solution: High output with optimized material usage.

- Energy-Saving Features: Designed to minimize power consumption, ensuring efficient operation while reducing energy costs.

Contact us today to learn more about our Automatic Paper Cone Making Machine and benefit your production process.

Contact Us

ENQUIRY FORM SODALTECH

Don't hesitate to contact us if you would like to know more about what we can do for you.