- Home

- About Us

- Machinery

- Paper Cone Production Line

Automatic Paper Cone Plant

-

Automatic Paper Cone Making Machine with Online Drier

-

Automatic Paper Cone Finishing Machine (Twin Index)

Semi Automatic Paper Cone Plant

-

- Paper Tube & Core Production Line

- Composite Can Production Line

- Pulp Moulding Production Line

- Tableware Production Line

- Edge Protector Production Line

- Fibre Drum Production Line

- Square Drum Production Line

- Paper Cone Production Line

- Products

- Projects

- CSR

- Contact Us

- Home

- Machinery

- Paper Cone Production Line

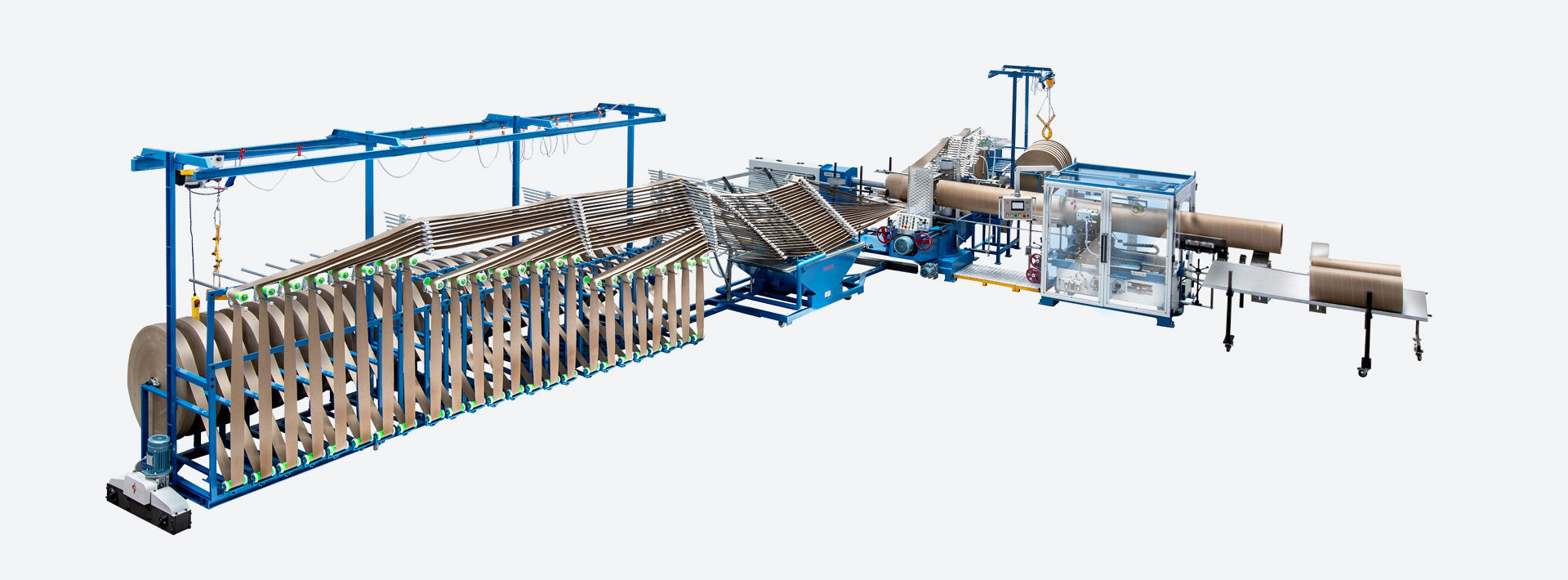

- Paper Cone Finishing Machine (Multi Process)

The Paper Cone Finishing Machine (Multi-Process) is a versatile machine designed to handle multiple finishing processes in one setup. This machine is ideal for manufacturers looking to streamline their production line and improve efficiency.

Key Features

html

Copy code

- Performs base cutting, grooving, bull nosing, velvet finishing, and automatic counting cum nesting operations in a single machine.

- Features easy interchangeability of mandrels and abrasive belts.

- Automatic indexing of cones as per operational sequence.

- Adjustable settings for bull nosing pressure, cutting depth, and nosing axis.

- Versatile for cone tapers: 3°30′, 4°20′, 5°57′, etc.

- Smart mechanisms to improve durability:

- Disengages cutting knife and air ejection when no cone is present.

- Prevents velvet finishing without a cone, extending emery belt life.

- Output: Up to 32 cones/minute, depending on the operator’s efficiency.

Machinery Videos

Exporting to more than 70 Countries

Why Choose Sodaltech

- Efficient Production Process: Tailored to meet various cone manufacturing needs.

- Sustainability: Supports recycling, reducing waste and reliance on virgin raw materials.

- Easy to Operate: User-friendly design ensures smooth functionality.

- Customizable Features: Adjustable for cone sizes, shapes, and additional requirements.

- Cost-Effective Solution: High output with optimized material usage.

Improve your production with our Multi-Process Paper Cone Finishing Machine. Contact us for a detailed quote and more information.

Contact Us

ENQUIRY FORM SODALTECH

Don't hesitate to contact us if you would like to know more about what we can do for you.