- Home

- About Us

- Machinery

- Paper Cone Production Line

Automatic Paper Cone Plant

-

Automatic Paper Cone Making Machine with Online Drier

-

Automatic Paper Cone Finishing Machine (Twin Index)

Semi Automatic Paper Cone Plant

-

- Paper Tube & Core Production Line

- Composite Can Production Line

- Pulp Moulding Production Line

- Tableware Production Line

- Edge Protector Production Line

- Fibre Drum Production Line

- Square Drum Production Line

- Paper Cone Production Line

- Products

- Projects

- CSR

- Contact Us

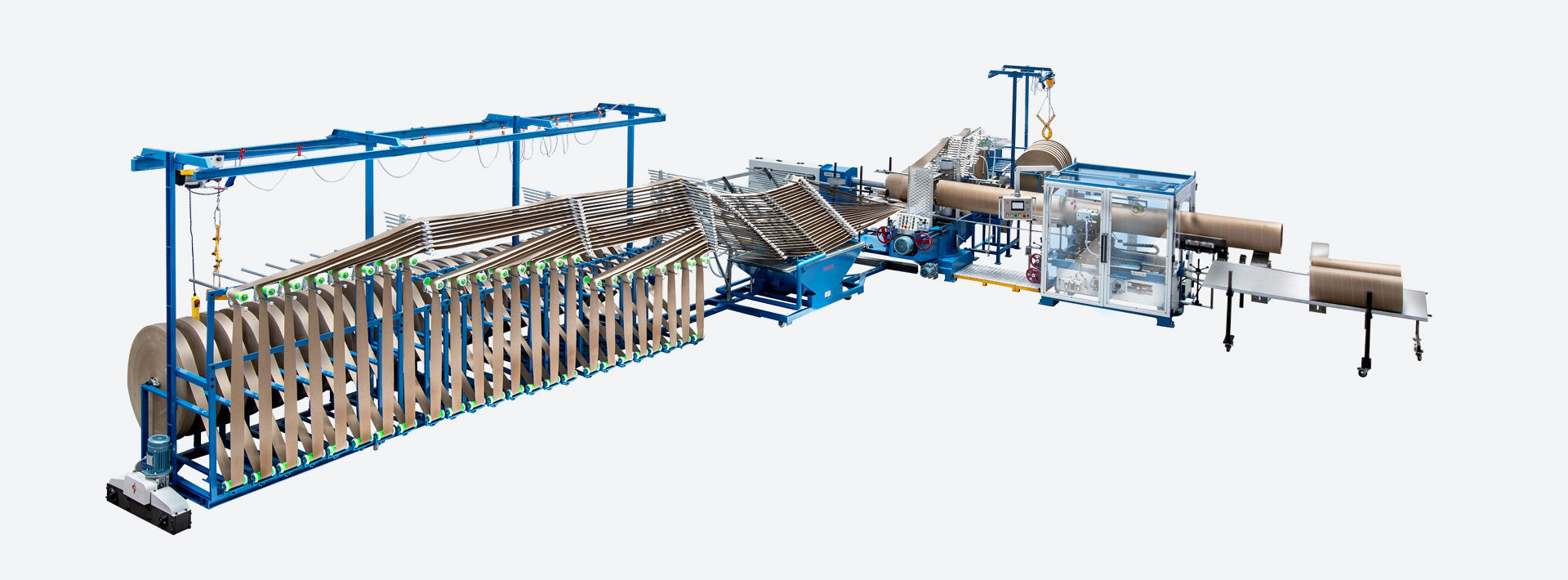

Composite Can Plant

COMPOSITE CAN PRODUCTION LINE

| Activity | To manufacture Composite Cans for packaging of various products |

| Type of Products | Composite Cans for packaging of detergents, liquor bottles, automobile Components, engineering goods, laminated cans for packaging of potato wafers, fruit drink, etc. |

| Size |

|

| Output @ 100% Efficiency | 30,000 cans per day of 24 hours operation depending upon the sizes |

| Plant & Machinery |

|

| Factory Shed | 400 Sq. mtrs (approx). |

| Power Required (Approx) | 9 KW |

| Labour Required | 4 direct operators / shift |

| Raw Material Requirement | Recycled kraft paper reels, synthetic resin adhesive or starch based dextrine |

| Technical Know- How, In-Plant, Training And Marketing Guidance | As SODALTECH has their own paper products division, an extensive training and guidance are provided alongwith latest technical know-how at reasonable extra cost. |

| Optional Equipments |

|

Note

The production capacity indicated above is only approximate and does not include any tool changing times or similar. The production efficiency and the output figures may vary in practical operation according to sizes of the products, operator efficiency, weather etc.

ENQUIRY FORM SODALTECH

Don't hesitate to contact us if you would like to know more about what we can do for you.